2-Ethylhexyl Thioglycolate: A Comprehensive Look at Its Past, Present, and Future

Historical Development

2-Ethylhexyl thioglycolate sprang from a wave of mid-20th-century chemical research aimed at surfactants and specialty reagents. As the market started to demand milder, more specialized chemical intermediates, especially for polymer and cosmetic sectors, thioglycolate esters carved out a niche. European and American chemists began isolating higher alkyl esters, finding that adding larger chains like 2-ethylhexyl tipped the balance between hydrophilicity and oil solubility. My experience working with raw materials for the plastics industry showed how small changes to a molecule’s tail can shift its whole role, a lesson crystallized here. By the late 1960s, companies had set technical standards for purity, sulfur content, and moisture, and global supply chains wove this reagent into production systems.

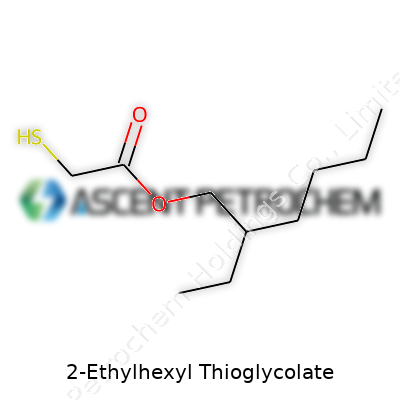

Product Overview

2-Ethylhexyl thioglycolate falls under the family of organosulfur compounds, precisely, the thiolesters of glycolic acid. Producers usually offer it as a clear, oily liquid packed in metal or HDPE drums. At the most basic level, this chemical helps modify polymers by acting as a chain-transfer agent. Its role stretches beyond one field: you’ll find it in making polyvinyl chloride (PVC) flexible and controlling molecular weights of specialty resins. I’ve witnessed factory floors where switching out a chain-transfer agent like this alters the very texture and usability of a batch of sheet vinyl or shoe sole material.

Physical & Chemical Properties

Sitting in the lab, anyone notices its colorless to pale yellow liquid form. With a typical density of roughly 1.03 g/cm3 at room temperature and a boiling point climbing past 295°C, it stays stable in most regular warehouse settings. That trademark sulfurous scent signals its identity even without a label. It barely dissolves in water; instead, it mixes best with organic solvents such as chloroform or ether. Chemists value its free thiol group that reacts fast with alkyl halides, unsaturated polymers, or peroxides, while its ethylhexyl chain hands it decent solubility in oilier formulations.

Technical Specifications & Labeling

Industry customers expect clear reporting. Material shipped from reputable suppliers must meet thresholds: purity not less than 98%, free acid under 0.2%, water content below 0.1%. Labels include UN shipping codes and hazard warnings, as this chemical falls under acute toxic and environmental hazard categories. Regulations in North America and Europe set clear upper limits for worker exposure. Every drum or container carries a lot number, batch date, and a safety data sheet (SDS) with specifics to guide onsite handling and medical care if needed. Chemical traceability and accuracy mark modern supply chains, a far cry from the ad-hoc practices in earlier decades.

Preparation Method

Manufacturers usually kick off by reacting 2-ethylhexanol with thioglycolic acid in the presence of acid catalysts. This esterification runs at elevated temperatures; water produced during the reaction gets siphoned off to drive the equilibrium toward the product. Insight from process engineers shows fine-tuning temperature, mixing speeds, and reactant ratios affects both the yield and cleanliness of the product. Careful control minimizes the formation of disulfides or side esters, which cause headaches during purification. I’ve seen pilot plant batches go awry from simple mistakes with catalyst addition, showing the value of experience even with routine syntheses.

Chemical Reactions & Modifications

This molecule’s allure lies in its reactivity. The free thiol grabs onto double bonds or forms linkages with metals, making it a favorite for anchoring soft PVC plasticizers or controlling peroxide-catalyzed polymerizations. In labs, chemists grab this chemical when synthesizing metal chelates or introducing customized functional groups. Environmental engineers have tested it as a temporary scavenger for heavy metals in waste streams; that sulfur atom locks onto lead, cadmium, or mercury, pulling them from solution. Modification often comes by swapping out the alkyl chain, but for oil-phase applications, that 2-ethylhexyl branch balances reactivity and process compatibility. Lessons from these modifications filter back, guiding next-gen versions with tailored chains for improved selectivity or water resistance.

Synonyms & Product Names

Across the market, it appears as 2-ethylhexyl mercaptoacetate, octyl thioglycolate, or sometimes just EHMA. European catalogs list it under EHTG or 2EH-TGA. Accurate product naming prevents substitution errors on plant floors, where mislabeling leads to costly batch remediation. Distributors and manufacturers use globally recognized IDs, harmonized under CAS number 7659-86-1, so buyers and shippers stay aligned.

Safety & Operational Standards

Ask anyone who’s handled thioglycolates: these compounds demand respect. Vapor contact irritates mucous membranes; skin exposure delivers fast-onset dermatitis. Personal protective equipment—nitrile gloves, splash goggles, and local exhaust ventilation—blocks most common routes of exposure. Facilities store drums away from sunlight and sources of oxidizers or acids, since uncontrolled reactions release heat and toxic fumes. Sites often train workers with simulated spill drills; I’ve seen accidental releases during unloading, and fast response limited both injury and downtime. Regular monitoring of air and wastewater for sulfur and organic load keeps environmental impact within legal limits.

Application Area

The PVC plasticizer sector counts among its chief clients, where small tweaks in processing let 2-ethylhexyl thioglycolate tune softness and flexibility. Textile auxiliaries, specialty inks, and adhesives benefit from its ability to massage polymer length and crosslink density. Hair removal products for depilatories once relied on related thioglycolates; regulatory scrutiny and skin safety research now limits this use in consumer goods, but industrial depilatories and animal hide treatments still draw on its strong keratin-breaking action. In my own years collaborating with R&D on custom resins, this chemical often became the pivot point for switching from brittle to flexible outputs.

Research & Development

Academic and corporate labs dig deep into structure-property relationships for this compound. Researchers test tweaks—shorter or branched alkyl tails, introducing aryl rings—comparing how minor edits change volatility, reactivity, and migration in finished plastics. Eco-tox studies probe alternatives that curb migration out of consumer-facing goods or degrade more safely in landfills. The last few years have brought collaborations between synthetic chemists and hazards analysts, with pilot projects exploring enzyme-resistant or low-odor variants for medical device coatings. My own exchanges with polymer scientists show that feedback between lab and shop floor drives the next iteration—test, adapt, and retest until performance and safety line up.

Toxicity Research

Research on 2-ethylhexyl thioglycolate’s health impact continues to surface, led by concerns about skin and eye irritation and acute toxicity on inhalation or ingestion. Animal studies point to moderate oral toxicity levels, and repeated exposure brings risk of cumulative organ damage. Environmental persistence remains a hot button; breakdown rates in sludge or river water lag behind some greener alternatives. Regulatory bodies in Europe and Asia tighten labeling and usage rules in proportion to these risks. Where product designers lean on this compound, they now run in-vitro screenings for breakdown products, plugging new data into chemical safety assessments before large-scale shifts hit the market.

Future Prospects

Looking ahead, 2-ethylhexyl thioglycolate faces both challenge and opportunity. Shorter, less persistent molecular cousins enter the market under green chemistry banners, yet this compound holds its grip in applications that demand oil solubility and robust chain control. Innovation swirls around making analogs with safer toxicological footprints or integrating this functional group into larger surfactant or catalyst packages. Policy changes, especially in the EU and North America, push manufacturers to revisit legacy recipes; investment pours into predictive toxicology to suit stricter REACH and TSCA rules. Conversations with process managers at chemical plants highlight two big needs for the future: dialing in efficiency to minimize waste, and designing fallback options if regulatory winds shift. In the world of specialty chemicals, adaptation and vigilance never go out of style.

Behind the Scenes in Manufacturing

Anyone who has walked the aisles of a drugstore looking at hair treatments or checked the label on an industrial cleaner may have run into words like “thioglycolate” before. It’s one of those chemical names that doesn’t easily roll off the tongue, but it plays a real part in making things we use every day work the way we expect them to.

2-Ethylhexyl thioglycolate comes from a group of chemicals called thiols mixed with glycolic acid. By itself, it’s not especially famous. But mixed and reacted with other stuff, it becomes useful in ways that don’t always grab headlines, though the results touch everyday lives. In manufacturing, this compound often works as a stabilizer and a so-called “modifier.” It keeps materials from reacting in ways we don’t want. It tames the wild side of certain formulas. Companies use it to keep their products steady during production, so nobody ends up with a product that turns or spoils too soon.

Hair Care and Beyond

Most folks will never see a jug of 2-ethylhexyl thioglycolate sitting on a store shelf. Still, anyone who’s ever straightened their hair or gotten a perm depends on its magic. It works within the powerful chemical cocktails that let stylists reshape hair by breaking and reforming its main protein bonds. Without compounds like this one, a perm or relaxer wouldn’t be possible—at least not in a way that customers find predictable. People want to walk out of a salon with strong, consistent results and not worry about damage or failed attempts.

Cosmetic companies appreciate how it helps control reactions. Too much activity in a product can lead to chemical burns or hair that snaps and splits. I’ve talked to stylists who really lean on reliable chemistry for safe services. It’s also why regulatory agencies keep a sharp eye on ingredients like these, pushing for safety studies and limits on use.

Other Uses: Plastics, Lubricants, Cleaners

This chemical doesn’t just show up in beauty products. It pops up on the industrial side, too, playing a quiet but significant role. Plastic makers blend it in during production to handle heat and pressure. It helps keep polymers from getting too brittle or too soft during the forming process. Additive makers use it for plasticizers, which are chemicals that keep plastics bendable and not cracking apart.

Manufacturers of lubricants and certain specialty cleaners sprinkle it into the mix to boost cleaning power or enhance flexibility. It can work as a scavenger for metals, helping prevent trace metals from messing up entire production batches. This matters where cleanliness or longevity really count.

Risks and Responsible Use

Like lots of specialty chemicals, 2-ethylhexyl thioglycolate isn’t something to toss around lightly. I’ve seen industry guidelines that focus hard on worker protection—goggles, gloves, the works. Toxicity studies suggest heavy exposure can irritate eyes, skin, and lungs. This is not something for kitchen science. Companies with sense follow strict handling procedures and keep it away from home use.

On the positive side, regulators set tight controls for products that might land close to people, especially cosmetics. Regular reviews mean the average consumer rarely faces high exposure. Industry groups talk about removing or substituting these types of compounds where safer options exist, especially for cosmetic uses, using guidance from ongoing research rather than waiting for disaster.

Building Safe, Effective Products

Finding balance is key. Modern manufacturing lives on the line between performance and safety. It’s easy to forget how much behind-the-scenes chemistry goes into familiar things—stronger plastics, gentler hair treatments, even cleaners that don’t give off nasty fumes. By keeping an eye on ingredients like 2-ethylhexyl thioglycolate, the industry moves toward better products and safer work conditions for everyone, while still delivering the results customers expect.

Looking Closely at What’s on the Label

Most people working in manufacturing or labs come across chemicals with strange names and even stranger warnings. 2-Ethylhexyl thioglycolate falls into that bucket. It’s used as a stabilizer and chemical intermediate, showing up in PVC processing or making certain specialty plastics. When I first glanced at the label of a sample bottle during my early days in chemical research, I didn’t expect it to be all that different from the other additives on the shelf. Still, a closer look gave me pause. The safety data sheet consistently flagged the stuff as hazardous—skin and eye irritant, risk of allergic reactions, and a warning about its strong, sulfur-like smell.

Why Real-World Safety Matters

Plenty of people trust their laboratory coats and gloves to do all the heavy lifting. Yet, direct handling of 2-ethylhexyl thioglycolate, even with its faintly oily texture, brings a long list of hidden risks. Research from National Center for Biotechnology Information highlights that this chemical triggers dermatitis for some, especially if used without proper moisture barriers. Even a few small splashes can cause redness, burning, or worse if they land in your eye.

There’s also the respiratory factor. Volatile vapors, though not always obvious, can irritate your lungs and throat during extended exposure, especially in workspaces with poor ventilation. Occupational exposure studies in Europe and Asia connect improper handling with an uptick in respiratory complaints among factory technicians.

Experience as a Teacher

My team ran a small PVC compounding project, and one careless moment with an open flask left someone coughing and uncomfortable for hours. No hospital trip, but it drove home the point: it isn’t just a “mild irritant” like some labels claim. On a larger scale, improper storage leads to leaks or evaporation. Even slight heat ups, like bottles sitting by a sunny window, can spread fumes around the shop floor.

Better Ways to Handle Risk

Things get better with knowledge and preparation. Most chemical safety experts recommend double-layered gloves, tight goggles, and ensuring any container stays sealed when not in use. Fume hoods, not just open windows, help catch lingering vapors. Quick access to eyewash stations and showers can turn a small mistake into an annoying incident rather than a disaster. Safety data sheets, often left buried under paperwork, matter in the real world; they list every symptom and necessary first aid measure. Even seasoned workers—sometimes especially them—benefit from brushing up on the basics each year.

Prevention Over Reaction

Easy solutions beat medical emergencies every time. Avoid transferring this chemical over desktops or in cluttered spaces. Spills should get treated immediately with absorbent pads and disposed of as hazardous waste, not swept under the rug or drained away. Supervisors should push for regular safety audits to cut down on complacency. In places where training costs seem high, just one incident will show how much more expensive it gets to skip good habits.

Regulations from OSHA and European chemical safety agencies guide the use of chemicals like 2-ethylhexyl thioglycolate, and agencies continue to tighten rules as new evidence comes in. For anyone dealing with it day in and day out, relying on luck and thin gloves isn’t enough. Safe handling means fewer days lost to injuries, more trust in the workspace, and healthier lungs twenty years down the road.

Why Storing 2-Ethylhexyl Thioglycolate Demands Respect

2-Ethylhexyl thioglycolate, a chemical often used in plastics and polymer industries, acts as a stabilizer and antioxidant in a wide range of products. This compound shows up everywhere from PVC flooring to adhesives, but its value depends heavily on how you store it. Many who work in production plants or small chemical facilities might overlook just how fast a storage mistake can lead to wasted inventory, health hazards, or avoidable fines.

Key Properties Driving Safe Storage

2-Ethylhexyl thioglycolate sits on the shelf as a pale yellow to colorless liquid, giving off a mercaptan odor that certainly grabs attention. This chemical works best below 25°C. Left in a warm area or exposed to sunlight, it can degrade, which affects product quality and can trigger unexpected reactions as it starts to break down. The liquid reacts with strong acids, strong bases, and oxidizing agents. If a leak or mixing accident happens, no one wants to be around for the smell or cleanup.

The Hands-on Side of Storage

In my time working alongside warehouse technicians, the lessons always felt clear: don’t leave 2-Ethylhexyl thioglycolate containers open or out in the sun. The best practice: keep it in tightly sealed drums or stainless-steel tanks. Galvanized steel, copper, or similar metals spell trouble, as they can set off reactions that run from annoying to dangerous. Think of the right container as cheap insurance that beats spending the weekend wrangling with a chemical spill team.

Low humidity and proper air flow give extra protection against vapor build-up. In smaller storage spaces or warehouses without HVAC controls, I saw storage rooms set up with simple fans and dehumidifiers. As for labeling, clear hazard pictograms trump handwritten stickers and help new team members spot risky materials instantly.

Thinking Past the Day-to-Day

Many operators worry about leaks but forget about vapor. Even a slight odor means vapor has escaped and, with it, potential health risks such as headaches or skin irritation. Providing nitrile gloves and splash goggles remains the easiest way to shield workers from nasty accidents. Even so, the best shield is a well-informed team. In small shops and large factories alike, regular training sessions on spill response and container handling usually prove more valuable than high-end monitoring gear. As I’ve seen, people take rules seriously when they know why they exist.

Spills do happen. Absorbent pads, sand, and chemical neutralizers lined the shelves in every facility where I worked. Anyone grabbing for a mop or towel probably doesn’t understand this chemical. A quick scoop with the right neutralizer outshines hours wrestling with secondary contamination.

Improving Safety and Sustainability

Shifting towards reusable or returnable containers offers both safety and environmental benefits. Many suppliers now accept empty drums for cleaning and reuse, cutting down on waste. Monitoring temperature and humidity with basic sensors costs little and helps keep storage conditions steady year-round. I saw plant managers who prioritized these basics enjoy fewer headaches, fewer compliance issues, and happier teams.

Straightforward precautions make a world of difference with 2-Ethylhexyl thioglycolate. With thoughtful storage, clear labeling, and practical training, plant workers keep people safe, preserve product quality, and stay ahead of costly problems.

Breaking Down the Compound

2-Ethylhexyl thioglycolate carries the chemical formula C10H20O2S. At first glance, it just looks like another set of letters and numbers—a secret code for chemists. But getting this formula right matters in the real world. The backbone of this molecule, 2-ethylhexyl, hooks up with a thioglycolic acid group, folding together into a molecule used in industries you probably interact with every single day.

Real-Life Uses and Why Precision Counts

Most people don’t pause to think about what goes into making a strong, flexible plastic or an effective cosmetic emulsion. Each component, even at the molecular level, needs to line up just right. 2-Ethylhexyl thioglycolate steps in as a stabilizer and an additive in polyvinyl chloride (PVC) production. The chemical makeup determines how it defends against degradation under sunlight and heat. Miss a single atom in that formula and the stability drops, leading to cracks, yellowing, or breakdown of the final material. Those shortfalls make their way into everyday products—think of electrical cables, flooring, even piping.

Safety and Human Exposure

Working with chemicals like 2-ethylhexyl thioglycolate needs care. In the lab, strong-smelling vapors and potential skin irritation cause chemists to suit up. The molecular formula shows just one sulfur atom, and that tells us two things: distinct odors and the need for thorough ventilation. Swapping out this compound for another or messing with the molecular balance can trigger health issues or product recalls, as strict rules protect both workers and end users.

Environmental Concerns

After spending years around labs, I’ve seen the impact of chemical runoff and poorly-disposed industrial waste firsthand. Even small shifts in the chemical structure change how fast a compound breaks down in the environment. A stable compound resists environmental assault, and regulators rely on precise formulas to track toxicity and persistence. 2-Ethylhexyl thioglycolate’s formula, C10H20O2S, dictates how it moves and breaks down in water supplies or soil, making it crucial for prevention of long-term damage.

The Demand for Transparency

Consumers want to know what’s inside the products they use. A clear chemical formula satisfies global standards for labeling and safety datasheets. People look for products that don’t raise red flags. As a parent and a science communicator, plain answers in chemical formulas go a long way toward building trust. Keeping that formula consistent across markets means regulators, manufacturers, and the public speak the same language—a necessary step as supply chains stretch across borders.

Improving Oversight and Responsibility

If we want safer plastics, better cosmetics, or greener manufacturing, tracking molecules by their formulas should be the minimum standard. To strengthen safety, workplace training must focus on recognizing compounds like 2-ethylhexyl thioglycolate just as easily as flour or salt. Environmental labs need fast, reliable methods to detect such compounds in surface and drinking water—no time for guesswork, since early detection helps avert community health risks. Pushing for more robust oversight stands as the best solution, so every molecule’s formula remains public, consistent, and backed by real science.

The Chemical’s Place in Global Trade

2-Ethylhexyl thioglycolate might not show up in conversations outside of a chemistry class or factory floor, but those who work with specialty chemicals know it gets plenty of attention during cross-border trade. It’s useful in making certain polymers and stabilizers, crucial for folks running manufacturing lines. But before packing up drums of this liquid and booking freight to another country, there’s a tangle of shipping hurdles to consider.

Complex Regulations Aren’t Just Fine Print

Trust grows easier when people see you follow laws and apply safety precautions. In my early years working with specialty chemicals, I watched an entire container flagged at a port, not because of sloppy packaging, but because the paperwork didn’t line up with the destination’s controls. Authorities want evidence it won’t harm people or the environment. Customs officials in Europe or North America want data on toxicity and flammability. Some Asian countries call for even more—unique import licenses and detailed chemical inventories. Getting details right isn’t about ticking boxes, it’s about showing everyone involved that care has been taken at every step.

Hazard Labels Matter—Even After the Factory Gate

From the first time I handled the stuff, the sharp odor let me know right away it’s not for casual use. It’s a skin irritant and fumes shouldn’t be ignored. Regulations around hazard labeling continue long after the initial purchase. The Globally Harmonized System (GHS) lays out standards for pictograms and safety phrases. Shipments missing this step face delays, and in some countries, on-the-spot destruction. If a drum leaks in a truck or at a port, the risk multiplies. I’ve seen emergency services show up, shutting down business while cleaning up a spill that stricter packaging or proper stickers might have prevented.

Supply Chains and Market Access

Supply isn’t just about how much you can make. Access depends on how you move material safely and legally. China, a big player in chemical manufacturing, controls exports through annual safety reviews and quota systems. Europe relies on REACH registration—which basically means the substance can’t enter the market unless suppliers prove it won’t harm health or the environment. The US enforces rules under the Toxic Substances Control Act (TSCA). Miss a beat and you find out shipment delays cost much more than compliance fees.

Challenges and Smarter Solutions

Supplying 2-ethylhexyl thioglycolate overseas comes with no shortcuts. Trying to skip steps to save time often backfires. Some companies have built in-house teams who track every export requirement, update Safety Data Sheets, and broker deals with certified shippers. Using experienced freight forwarders saves plenty of headaches—these folks stay in touch with customs officials and know the quirks of each market. Technology also makes a difference, like shared online portals to submit documents directly to authorities.

What encourages smoother trade isn’t relaxing standards, but raising the baseline of knowledge. Offering regular training, especially for folks preparing shipments, pays off. Smarter packaging—double-sealed, shockproof containers—reduces accident risks. Stronger industry networks mean companies can share updates on rule changes quick enough to avoid supply chain chaos. It takes effort and constant learning to play by these rules, but the benefits reach further than one shipment. Health, safety, and reputation last beyond customs checks.

| Names | |

| Preferred IUPAC name | 2-ethylhexyl 2-sulfanylacetate |

| Other names |

2-Ethylhexyl mercaptoacetate

2-Ethylhexyl thiolacetate Mercaptoacetic acid 2-ethylhexyl ester |

| Pronunciation | /tuː ˌɛθ.ɪlˈhɛk.sɪl ˌθaɪ.oʊˈɡlaɪ.kə.leɪt/ |

| Identifiers | |

| CAS Number | 7659-86-1 |

| Beilstein Reference | 1698734 |

| ChEBI | CHEBI:87147 |

| ChEMBL | CHEMBL609197 |

| ChemSpider | 2673726 |

| DrugBank | DB11262 |

| ECHA InfoCard | 03f226d9-9109-3eb7-ba3f-1eb1c3437ca1 |

| EC Number | 211-927-9 |

| Gmelin Reference | 84888 |

| KEGG | C18621 |

| MeSH | D017209 |

| PubChem CID | 12521 |

| RTECS number | KM2975000 |

| UNII | L09KPH9O39 |

| UN number | UN3334 |

| CompTox Dashboard (EPA) | DTXSID4047103 |

| Properties | |

| Chemical formula | C10H20O2S |

| Molar mass | 194.32 g/mol |

| Appearance | Colorless transparent liquid |

| Odor | Strong, unpleasant |

| Density | 1.024 g/cm3 |

| Solubility in water | Slightly soluble |

| log P | 4.09 |

| Vapor pressure | <0.1 mmHg (20 °C) |

| Acidity (pKa) | 9.85 |

| Basicity (pKb) | 2.6 |

| Magnetic susceptibility (χ) | -7.38×10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.484 |

| Viscosity | 4.5 mPa·s (20°C) |

| Dipole moment | 2.75 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 472.6 J/mol·K |

| Std enthalpy of formation (ΔfH⦵298) | -425.1 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | –810.1 kJ/mol |

| Pharmacology | |

| ATC code | D10BX |

| Hazards | |

| GHS labelling | GHS02, GHS07 |

| Pictograms | GHS05,GHS07 |

| Signal word | Warning |

| Hazard statements | H302, H315, H319, H400 |

| Precautionary statements | P210, P261, P273, P302+P352, P305+P351+P338, P333+P313 |

| Flash point | 113°C (closed cup) |

| Autoignition temperature | 360 °C |

| Lethal dose or concentration | LD50 (oral, rat): 2080 mg/kg |

| LD50 (median dose) | LD50 (median dose): Oral Rat 2591 mg/kg |

| PEL (Permissible) | PEL (Permissible Exposure Limit) for 2-Ethylhexyl Thioglycolate: Not established |

| REL (Recommended) | 0.2 ppm |

| Related compounds | |

| Related compounds |

Thioglycolic acid

Methyl thioglycolate Ethyl thioglycolate Butyl thioglycolate Isopropyl thioglycolate Dodecyl thioglycolate |