2-Mercaptoethanol: An In-Depth Commentary

Historical Development

2-Mercaptoethanol made its appearance in the chemical world back in the 1930s, meeting needs in laboratories where classical reducing agents showed their limits. In university research settings and commercial chemistry, chemists sought more efficient agents for breaking disulfide bonds, and so 2-mercaptoethanol entered the scene. The compound didn’t shoot to fame overnight. It took years for researchers to recognize its potential in protein chemistry and in the manufacture of certain plastics and pharmaceuticals. Early work focused on dialing in preparation methods to limit unwanted side products or nasty smells, which any lab worker will tell you lingers far too long on any surface or glove.

Product Overview

2-Mercaptoethanol, known in labs by the shorthand BME, holds a special place as a reducing agent. Its clear, syrupy liquid consistency and sharp odor mark it out immediately during handling. Modern suppliers push its purity to the 99% range, bottling it in volumes from 500 milliliters to industrial 25-liter carboys. The chemical industry finds it easy to use and ships it under strict rules to protect workers and environments from spills and vapor leaks. Labs lean on it to maintain reducing environments, especially in the preparation of cell extracts or in protein electrophoresis.

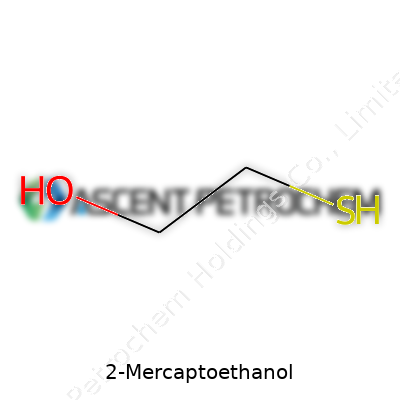

Physical & Chemical Properties

At room temperature, 2-mercaptoethanol holds a boiling point of around 157°C and a melting point just below -100°C. Its density sits just above that of water, at roughly 1.11 g/cm³. The compound mixes easily with water and many organic solvents, which makes cleaning up spills necessary and tricky in equal measure. Chemists watch out for its strong, sulfur-heavy odor, as even tiny concentrations waft through buildings. BME’s reactivity comes from its thiol group, which attacks disulfide bonds and carbonyl groups, putting it front and center in breakage reactions that target proteins, RNA, and DNA structures.

Technical Specifications & Labeling

Suppliers provide 2-mercaptoethanol with high purity, often surpassing 99%, and guarantee low levels of moisture and organic impurities. Labeling on standardized bottles spells out hazards, including flammable liquid, acute toxicity, and environmental risks. The GHS pictograms and risk statements tell all: corrosive, toxic by inhalation and skin contact, and dangerous for aquatic life. Certifications typically match global safety standards and batch lot numbers let buyers trace each shipment to its origin, ensuring full compliance from manufacturing through distribution to lab bench.

Preparation Method

Chemists manufacture 2-mercaptoethanol by the reaction of ethylene oxide with hydrogen sulfide. Controllers monitor temperatures and pressure closely, since both reactants come with their own set of hazards and require careful handling to avoid runaway reactions. Final purification strips away side products, water, and unreacted starting materials, so the product leaves the facility meeting strict technical specifications. Industrial producers use large-scale reactors while academic labs can manage small batches for research needs.

Chemical Reactions & Modifications

In the lab, 2-mercaptoethanol shines as a strong nucleophile thanks to its thiol group. It tears through disulfide bonds in peptides or proteins, making it essential in protein denaturation and sample preparation for electrophoresis or mass spectrometry. It also reduces aldehydes and ketones, and forms thioesters and disulfides during synthetic procedures. Chemists have found ways to tweak its structure, swapping out the ethyl group or tying it onto more complex backbones, opening up space for research in areas like medicinal chemistry or specialized ligands.

Synonyms & Product Names

In catalogs, 2-mercaptoethanol often appears as BME, β-mercaptoethanol, or simply “thioglycol.” The IUPAC system names it as “2-sulfanylethanol,” which you might spot in regulatory or technical documents. Variations pop up in different languages or regions, but across scientific fields, BME holds widespread recognition.

Safety & Operational Standards

Anyone working with 2-mercaptoethanol understands the real need for proper ventilation and protective equipment. Fume hoods, gloves, and face protection keep technicians safe from both the vapor and accidental contact. Its low odor threshold means leaks get detected quickly, but also raises headaches for those working in cramped or poorly ventilated labs. Waste must be disposed of as hazardous chemical waste, never poured down the drain. Many countries require training and written standard operating procedures before staff use BME, and storage cabinets for volatile organics often come equipped with vapor sensors or spill containment.

Application Area

Molecular biology labs reach for 2-mercaptoethanol to protect RNA samples from oxidative degradation—tiny amounts keep RNase enzymes inactive, which matters for clean experimental results. Protein scientists and biotechnologists use it to disrupt disulfide bonds, opening up polypeptides for sequencing or structural analysis. Industrial applications branch out from plastics stabilizer to pharmaceuticals intermediate and even specialty coatings where reducing power or unique chemical reactivity brings value. The textile sector has used BME in wool processing, peeling away unwanted bonds without triggering large-scale fiber damage.

Research & Development

Research continues to explore alternatives to 2-mercaptoethanol with fewer health or environmental concerns. Some lab groups pursue analogs that offer similar reactivity but with less pungent smells or lower volatility. Chemists dig into the structure-activity relationship, hunting modifications that cut down toxicity without losing effectiveness. High-throughput screening platforms evaluate not just reactivity but long-term shelf stability and ease of handling. Biologists look for replacements that don’t interfere with downstream assays or cellular machinery, since even small traces of BME can disrupt sensitive detection technologies.

Toxicity Research

2-Mercaptoethanol presents a real risk to workers, with headaches, nausea, and serious respiratory symptoms possible from chronic exposure. Early studies flagged it for strong acute effects on the central nervous system and the liver in animals. Chronic studies in rodents and rabbits suggested reproductive toxicity and carcinogenicity at high doses, pushing for even tighter workplace controls in recent years. Today, chemical safety agencies direct regular air and surface monitoring and require rigorous personal protective measures for those handling concentrated material.

Future Prospects

Researchers look ahead to safer, cleaner chemistry, and many feel motivated to replace 2-mercaptoethanol outside the most necessary lab settings. Improved engineering controls, tighter labeling, and expansion of dedicated alternatives push the chemical into more limited, higher-standards use. Green chemistry initiatives aim for compounds that break down quickly in the environment and leave behind fewer unsafe residues. Still, its cost and availability keep it stubbornly embedded in current protocols. As those in research keep pressure on suppliers and regulatory agencies, new formulations and technologies may finally shift demand away from BME toward next-generation solutions that combine safety with performance, without the historical baggage.

Breaking Down 2-Mercaptoethanol’s Everyday Importance

2-Mercaptoethanol doesn’t show up in everyday conversation for most people, but anyone who has spent time in a biology or chemistry lab has likely smelled it. The pungent odor alone sticks in the mind. I remember the first time I cracked open a bottle in college—the sharp stench made me realize pretty quickly this wasn’t a product to take lightly. The real importance of 2-Mercaptoethanol goes far beyond the smell, though.

A Go-To in Labs Worldwide

Research labs across the planet use 2-Mercaptoethanol for a very practical purpose: breaking down stubborn protein structures. Inside proteins, strong bridges made of sulfur keep them folded in precise shapes. If you want to study those proteins, you need to break those bridges. This is where 2-Mercaptoethanol comes in—its sulfur atom snaps the bonds apart, letting scientists unravel tricky proteins so they can figure out how they work or run them through an analysis. This step becomes vital for research in everything from basic biology to drug discovery. I have watched whole experiments grind to a halt simply because a shipment of it was delayed.

Earning Its Place in Cell Culture

Every scientist who’s worked with mammalian cells in petri dishes knows the importance of keeping those cells healthy and growing. 2-Mercaptoethanol finds its way into cell culture media for this reason. It acts as a reducing agent, lowering the chances of oxidative damage. Oxidative stress hurts cells, slows results, and drains research budgets. Fresh, active 2-Mercaptoethanol helps cells stay in better shape, so the data ends up more reliable. The impact here is real: experiments with and without this chemical can yield different results, leading to better reproducibility in research.

Beyond the Lab Bench

This chemical’s life doesn’t stop at biology research. In industrial settings, it shows up as a raw material in chemical production and as a stabilizer in different formulations. Workers producing plastics, rubbers, and resins encounter it frequently. Careful handling and proper training are essential. 2-Mercaptoethanol can harm if inhaled or touched in large quantities, so health and safety protocols protect people working with it. Trust plays a big part here—workers rely on companies to provide accurate material safety data sheets so everybody knows what kinds of risks are present and how to handle accidents.

Addressing Environmental and Safety Concerns

The chemical’s usefulness brings challenges. Disposal isn’t straightforward since toxic fumes and risks to water systems can arise if it’s dumped improperly. Factories and labs need established waste management systems and must keep up with local regulations. Some universities now teach green chemistry early in their programs, pushing students to think about both scientific utility and environmental impact. I’ve seen a big change just over the last decade—with more researchers looking for safer alternatives or ways to reduce how much 2-Mercaptoethanol they use overall.

Moving Toward Safer Practices

Better personal protective equipment and air filtration systems help limit exposure. Ongoing research digs for alternative chemicals that can break sulfur bridges without the same toxic effects. Until safer solutions become mainstream, the science and industrial communities keep balancing the upside of reliable data and production with the real-world impact of hazardous material use. Training, vigilance, and innovation together keep progress possible without sacrificing responsibility.

Understanding What You’re Working With

2-Mercaptoethanol isn’t something to take lightly in the lab. Known for its strong, rotten-egg smell, this chemical often shows up where scientists need to break down proteins. Its use stretches from research benches to industry setups, and its hazards come with the territory. The safety conversation goes beyond reading a label or glancing at a data sheet. It’s about practical steps that keep people safe when that sharp, sulfurous odor hangs in the air.

Personal Protective Equipment: Not Just for Show

Gloves do more than prevent a mess—they stand between your skin and a compound that can cause burns and irritation in seconds. Nitrile gloves hold up better than latex with 2-mercaptoethanol, and double-gloving offers extra peace of mind. Eye protection remains non-negotiable. A drop can burn the cornea and lead to a painful day in the emergency room. Laboratory coats, buttoned up tight, and chemical splash goggles block off major entry points for splashes and vapors.

Ventilation and Why It Matters

Without good airflow, the odor lingers and vapors linger, too. Even at low levels, breathing it in means risking headaches, nausea, and long-term effects. Working inside a chemical fume hood creates a safer breathing space, keeping those fumes away from your face. Relying on open windows or a regular exhaust fan doesn’t do the job—dedicated laboratory ventilation systems are essential, especially when mixing or transferring the chemical.

Spills and Cleanups: Moving Fast with a Plan

Spills happen fast, and they don’t wait for a convenient moment. Keeping absorbent pads and neutralizing agents within reach ensures a quick response. Small spills need careful blotting with absorbent materials, all while wearing gloves and keeping movement slow and deliberate. Bigger spills sometimes call for evacuation, and a practiced team handles cleanup gear after alerting others in the area. Every lab team I’ve worked with has a spill kit marked and easy to grab. Knowing exactly where that kit sits saves precious seconds.

Storage Concerns

Cool, well-ventilated cabinets provide the right spot for 2-mercaptoethanol. Airtight containers prevent leaks and minimize the spread of vapors. Storing this chemical away from strong acids, oxidizers, and open flames cuts down the risk of dangerous reactions. Over the years, I’ve seen negligent storage cause sticky residue or corrosion on shelves—a warning sign to check for leaks or faulty seals. Labeling keeps anyone reaching into a storage area informed and alert to hazards.

Training and Emergency Awareness

Even experienced chemists benefit from a refresher on handling 2-mercaptoethanol. Training should make the smell, symptoms, and safety procedures familiar. Quick recognition of skin or eye exposure can mean the difference between a minor irritation and a serious injury. I make it a priority to drill emergency eyewash and shower locations every quarter. Often, panic sets in when someone realizes they’ve been exposed, and muscle memory makes all the difference.

Safer Substitutes and Advanced Controls

Some teams look for safer alternatives, especially outside specialized research. Advances in chemical synthesis constantly push out toxic components like 2-mercaptoethanol where possible, but for many lab processes, nothing else does the trick. Risk can drop through automation, sealed transfer systems, and remote mixing equipment. The less time spent face-to-face with the compound, the lower the risk for everyone in the lab.

Why Safe Storage Matters

Anyone who has spent time in a lab will recognize the sharp, sulfurous whiff of 2-mercaptoethanol. Some people call it “stink bomb” liquid, and for good reason. Used as a reducing agent and protein stabilizer, its usefulness spans molecular biology and chemistry. But this stuff comes with real risks—breathing it, touching it, or letting a bottle leak means harm isn’t far off.

Real Hazards in Real Labs

More than just a bad smell, 2-mercaptoethanol attacks eyes, skin, and lungs. People who breathe it can wind up with headaches, dizziness or worse. Spills can ruin an entire day’s work, contaminate expensive equipment, and even harm the building’s infrastructure. Working with it for years taught me that a cavalier attitude toward storage invites trouble.

In the U.S., the Centers for Disease Control (CDC) and the National Institutes of Health (NIH) both flag this chemical as hazardous. Even a small splash can cause injury, while fumes can linger and contaminate other lab materials unless dealt with correctly. The Environmental Protection Agency (EPA) lists it in the Toxic Substances Control Act.

What Works in Practice

Lab pros know that 2-mercaptoethanol stays stable in cool and dry places. The bottle cannot sit near heat, direct sunlight, or open flames. Flammable liquid storage cabinets provide a real layer of protection. Chemical fridges set for non-food items handle the job, as ordinary kitchen fridges aren’t meant to contain corrosive fumes. That difference cuts down on accidental exposures.

Tight sealing keeps evaporation down and odors in check. I’ve seen more than one poorly tightened cap lead to headaches across an entire floor. Glass is better than plastic, as 2-mercaptoethanol breaks down many plastics over time. Amber glass adds an extra block against light, keeping the chemical from degrading.

Every good lab enforces label discipline. Proper hazard symbols and legible writing matter, especially for chemicals like this that tend to drift from one bench to the next. Spill trays under bottle storage work as a simple backup, keeping leaks from spreading.

Hard Lessons from Experience

Anyone claiming shortcuts work hasn’t watched a fume hood’s filter clog with this stuff, or had to evacuate after a spill. I still remember cleaning out a forgotten cabinet of expired chemicals. The only bottles swelling more were the ones stored wrong—kept warm, jostled by careless storage, or left uncapped for weeks. Reports from the American Chemical Society back this up: temperature swings accelerate decomposition, and that boosts vapor risk.

Simple Solutions, Stronger Safety

Old hands know you don’t have to upgrade the entire building for better storage. Choose chemical cabinets with rated ventilation, place containers where they won’t get knocked over, and check caps for a secure fit. Rotating stock helps too—new bottle in, old bottle out—so nothing sits past its prime.

For anyone unsure, the safety data sheet for 2-mercaptoethanol lays out essentials, and some labs post them above the chemical shelves. Training newcomers to reach for gloves and goggles before reaching for a bottle pays off, too. People develop habits fast, and starting with safe ones builds confidence—the kind that prevents accidents most.

A little care up front saves hours of cleanup and, more important, keeps colleagues healthy. Safe storage isn’t a theory—it’s a practice that protects everyone, from the newest student to the principal investigator.

Meet 2-Mercaptoethanol

Work in a lab long enough and eventually 2-mercaptoethanol crosses your path. You know it as a clear liquid that smells like rotten eggs, but its risks go far beyond its awful odor. Labs around the world use it for breaking protein bonds and controlling oxidation. That doesn’t mean it’s safe to handle. Far from it. Understanding these risks starts in the chemistry and ends in the body’s response.

Breathing and Touching: Health Risks Are Immediate

A single whiff of 2-mercaptoethanol feels harsh. Irritation hits your nose and throat within seconds. Eyes water, sometimes burn. Some workers have described intense nausea after short-term exposure. This liquid moves straight into the air because it easily evaporates, especially at room temperature. There’s no ignoring the direct effects of handling it without serious protection.

Contact with skin brings another problem. Even small splashes can cause redness and blistering. Unlike other chemicals that need volume to be dangerous, a single drop here matters. Getting it off quickly makes all the difference. If it soaks in, bigger problems develop—headaches, dizziness, possible vomiting. That’s partly because 2-mercaptoethanol can slip through skin into the bloodstream. So, gloves that actually resist chemicals go from optional to completely necessary.

Not Just a Lab Issue: Risks Grow With Poor Ventilation

Many stories from research labs involve leaking bottles or spills. Most buildings funnel fumes to vents, but older labs might rely on open windows or weak fans. The dangerous part comes when those fumes linger. Repeated inhalation means more than a momentary headache; over time, it can stress out organs like the liver and kidneys. Studies link chronic exposure to both cell and DNA damage. Not every scientist ends up with long-term effects, but those who do rarely saw it coming until symptoms appeared.

Fire Danger: Not Something to Ignore

On top of everything else, 2-mercaptoethanol is flammable. Stick it near heat or static and you’re flirting with a lab fire. Its low flash point means you can’t use it near open flames, sparks, or even hot equipment. Old, corroded containers raise the risk because vapor can leak where you least expect it. Combining chemical risk with a fire hazard spells even bigger trouble for facilities with lots of flammable solvents or paper materials stacked nearby.

What Can Be Done: Lessons From the Lab Bench

Training workers jumps straight to the top of the list. Every new lab member must know 2-mercaptoethanol’s hazards right away—not after the first exposure. Relying on instinct doesn’t cut it. Proper storage matters more than most think. I’ve seen a shelf stacked too high with reactive chemicals, bottles leaking onto cardboard. That’s asking for a spill nobody wants to handle. Storing this liquid tightly sealed, in clearly labeled containers, inside a chemical fume hood, keeps risks controlled.

Spill kits belong within reach, not locked in another room. Emergency showers and eyewash stations need regular testing. The only way to catch lingering vapors involves up-to-date ventilation and regular maintenance.

Gloves, goggles, and lab coats give some peace of mind. Swapping out torn gloves or wiping down goggles quickly becomes routine for those who work safely. Respect for 2-mercaptoethanol doesn’t come from lectures alone. It grows from hearing stories, watching accidents nearly happen, and never assuming this sulfur compound is just another harmless chemical.

Poking at Compatibility: Real-World Lab Experience

2-Mercaptoethanol. Just the smell alone makes you realize this isn’t your everyday chemical—it carries the sort of punch that reminds you to take your gloves and fume hood decisions seriously. For anyone working in biolabs, this is the chemical you often find in the back fridge—usually right by the DTT—because reducing disulfide bonds can change the entire landscape of a protein sample. People have asked me about mixing this chemical with other stuff, worried if it’ll spark something you really don’t want happening on a Monday morning.

Why 2-Mercaptoethanol Gets Added in the First Place

Let’s talk about what 2-Mercaptoethanol does, because it’s the “why” that gives us most of the answers about compatibility. Its big role is keeping proteins from sticking together by breaking sulfur bonds. Scientists add it to loading buffers for SDS-PAGE, or to lysis buffers before western blotting, so the proteins unwind and can be separated by size—instead of staying clumped together in their natural shape. So in a typical experiment, it changes the landscape for everything from enzymes to antibodies.

Who Are Its Chemical Friends (And Enemies)?

Here’s where the headaches start. 2-Mercaptoethanol is a reducing agent. If you mix it with something that likes to suck up electrons—think strong oxidizers—it can spark unexpected chemical reactions. For example, mixing this with hydrogen peroxide or bleach sets off dangerous gas and heat, and nobody wants that. Avoid oxidizers in the same space as this stuff, whether in your reagents or on a dirty bench.

SDS—used in SDS-PAGE—plays nice with 2-Mercaptoethanol. They work in partnership, tearing down both the protein shape and sticking power. But keep an eye on your metals: copper and iron ions don’t behave well with 2-Mercaptoethanol. The reaction swings too far, producing reactive oxygen species (think free radicals) that wreck proteins and DNA. If your experiment includes transition metals, especially copper in enzyme buffers, consider switching to a milder reducing agent or leaving metals out until later steps.

Lab Safety: Smell, Storage, and Mindset

There’s no escaping the stench of 2-Mercaptoethanol. That rotten cabbage smell gets into everything, which is actually handy—it lets you know instantly if you’ve had a spill. Always keep the stock bottle sealed and work with it inside a fume hood. Open bench work isn’t just bad manners, it’s risky for anyone walking through. Absorption through skin is fast, too, so double-glove and skip long exposures where you can. Wash your hands after use, even if you wore gloves the whole time. And don’t toss contaminated pipettes into the trash if your building lacks proper chemical disposal protocols.

Solving Compatibility Headaches

People sometimes add 2-Mercaptoethanol right before an experiment to sidestep reactions with other chemicals in storage. Dissolving it in water first and then adding to a buffer keeps concentrations accurate and avoids unwanted oxidation. Work in small batches to rotate stock and cut down on chemical decomposition. Use freshly made solutions whenever your experiment really counts—old 2-Mercaptoethanol can lose punch over time, especially if someone left the cap off. If mixing with tricky chemicals, check institutional chemical compatibility charts or talk to the safety officer. No experiment is worth an evacuation.

Taking the Smart Route in the Lab

Every experiment pushes you to weigh speed against safety. My own early mistakes—from using the wrong gloves to forgetting what was in a buffer—taught me that knowing how 2-Mercaptoethanol fits with other chemicals isn’t just book knowledge. It’s about protecting your results, your health, and the lab around you. Stay alert, know your reagents, and treat this chemical with respect.

| Names | |

| Preferred IUPAC name | 2-sulfanylethanol |

| Other names |

2-Hydroxyethyl mercaptan

β-Mercaptoethanol BME HSCH2CH2OH Mercaptoethanol Thioethylene glycol 2-Hydroxyethanethiol |

| Pronunciation | /tuː mɜːrˌkæptoʊ ˈɛθəˌnɒl/ |

| Identifiers | |

| CAS Number | 60-24-2 |

| Beilstein Reference | 63559 |

| ChEBI | CHEBI:35807 |

| ChEMBL | CHEMBL418 |

| ChemSpider | 680 |

| DrugBank | DB02726 |

| ECHA InfoCard | 03b6f0f1-4a3d-4bb5-93bc-2b3c08979eba |

| EC Number | 231-273-2 |

| Gmelin Reference | 82238 |

| KEGG | C00522 |

| MeSH | D008770 |

| PubChem CID | 1567 |

| RTECS number | KL5600000 |

| UNII | K858JZ4884 |

| UN number | UN2966 |

| Properties | |

| Chemical formula | C2H6OS |

| Molar mass | 78.13 g/mol |

| Appearance | Colorless to pale yellow liquid |

| Odor | Unpleasant, rotten-egg-like |

| Density | 1.114 g/mL at 25 °C (lit.) |

| Solubility in water | Miscible |

| log P | -0.36 |

| Vapor pressure | 0.8 mmHg (20°C) |

| Acidity (pKa) | 9.5 |

| Basicity (pKb) | 14.5 |

| Magnetic susceptibility (χ) | -49.5×10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.503 |

| Viscosity | 23 cP (20°C) |

| Dipole moment | 1.90 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 168.0 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -171.1 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -635.7 kJ/mol |

| Pharmacology | |

| ATC code | V03AB32 |

| Hazards | |

| GHS labelling | GHS02, GHS05, GHS06, GHS07 |

| Pictograms | GHS06,GHS05 |

| Signal word | Danger |

| Hazard statements | H302, H312, H315, H318, H331, H370 |

| Precautionary statements | P210, P261, P273, P280, P301+P310, P305+P351+P338, P308+P311, P403+P233, P501 |

| NFPA 704 (fire diamond) | 3-2-2-W |

| Flash point | 64 °C |

| Autoignition temperature | 285°C |

| Explosive limits | 4.1% - 19% |

| Lethal dose or concentration | LD50 oral rat 244 mg/kg |

| LD50 (median dose) | LD50 (median dose) of 2-Mercaptoethanol: 244 mg/kg (oral, rat) |

| NIOSH | KL2975000 |

| PEL (Permissible) | PEL: 1 ppm (5 mg/m3) (OSHA) |

| REL (Recommended) | 0.01 – 0.1% |

| IDLH (Immediate danger) | IDHL: 1 ppm |

| Related compounds | |

| Related compounds |

Ethanol

Ethylene glycol 1,2-Ethanedithiol Mercaptoacetic acid |