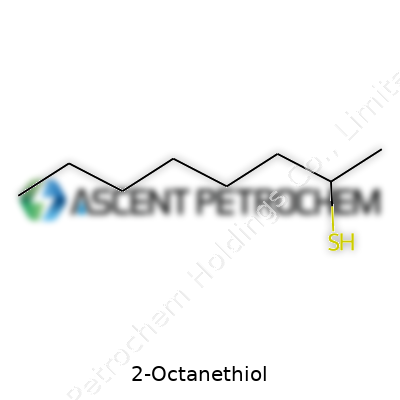

2-Octanethiol: In-Depth Discussion

Historical Development

Chemists have always viewed sulfur-containing organic compounds as a doorway to new reactions and applications. As long-chain alkanethiols began to draw interest through the twentieth century, 2-Octanethiol took its place in research labs and chemical production lines. Living through the boom of organic synthesis and the spread of petroleum chemistry, it came into commercial markets as both a laboratory curiosity and a workhorse raw material. The push for better lubricants, surfactants, and flavor agents further fueled its production, drawing on industrial advances in thiol handling and purification. This compound rode the wave of specialty chemicals emerging from rapid growth in the paint, rubber, and electronics markets.

Product Overview

2-Octanethiol, known for its characteristic heavy, pungent odor, forms part of the family of higher alkanethiols offering richer chemistry than shorter-chain relatives. Direct chemical suppliers, synthetic research organizations, and specialty labs handle this product in both pure and formulated grades, pairing high purity with reliable labeling and traceability. Whether sold by the drum or in analytical vials, the importance lies in control, clear documentation, and batch consistency. With my own hands, I’ve uncapped a flask and recognized the unique sulfur aroma right away—a sensory signal of its identity and potency.

Physical & Chemical Properties

With a molecular formula of C8H18S and a molar mass clocking in around 146.3 g/mol, 2-Octanethiol shows up as a colorless to pale yellow liquid. The density rests near 0.83 g/cm3, while its boiling point stretches past 200°C, making it manageable but not trivial under normal lab conditions. This chemical resists solubility in water but readily dissolves into organic solvents like ether and chloroform, opening doors for reaction setups or formulation blending. The presence of the thiol functional group brings a high degree of reactivity—especially in nucleophilic reactions, redox chemistry, and metal binding. Volatility brings both convenience and a need for careful ventilation, particularly during distillation or large-scale operations.

Technical Specifications & Labeling

Regulatory authorities ask for detailed labels on every bottle, with clear marking of CAS number 111-88-6, hazard pictograms, and statements for handling protocols. In chemical production, minimum assay parameters often hit or exceed 98%, with color and odor benchmarks checked batch by batch. Certificates of Analysis back up claims on purity, water content, and any trace impurities. For every order, handling instructions and Material Safety Data Sheets (MSDS) must match local workplace and shipping regulations, aiming to protect those storing, transferring, or disposing of this compound. Accuracy in labeling and two-step verification on receipt protect people and property from accidental mix-ups or exposures.

Preparation Method

Most commonly, manufacturers produce 2-Octanethiol through the addition of hydrogen sulfide to 2-octene in the presence of acid catalysts or through halide substitution routes—such as treating 2-chlorooctane with sodium hydrosulfide. The selection of synthetic route often rests on scale, impurities, and downstream needs. In the lab, reaction work-ups involve separation from reaction mixtures, careful extraction, and sometimes vacuum distillation for best results. The smell of hydrogen sulfide and thiols in the air always signifies the need for high-performance fume hoods and reliable scrubber systems. The challenge never fades; producing clean product at volume means juggling reaction kinetics, phase separation, and downstream purification.

Chemical Reactions & Modifications

The functional thiol group brings rich opportunities for transformation. Chemists use 2-Octanethiol as a nucleophile to attack electrophilic centers, introduce sulfur into organic frameworks, or anchor to gold and metal surfaces through self-assembled monolayers (SAMs). Oxidation produces disulfides or, under milder conditions, sulfoxides and sulfones. It supports hydrothiolation of alkenes, thioester synthesis, and click chemistry reactions. Not every structure responds the same way to a 2-Octanethiol modification; reactivity depends on solvent, temperature, and catalyst choices. My own experience with monolayer assembly on gold illustrates its ability to radically change surface properties, shifting electric conductivity and wettability for next-generation sensors.

Synonyms & Product Names

A chemical by any other name still stinks as strong: 2-Octanethiol also appears as Octane-2-thiol, 2-Mercaptooctane, or even Caprylmethyl mercaptan. Various chemical catalogs and safety documents keep lists up to date but the CAS number—111-88-6—clears up confusion fast. Local markets and specialty vendors sometimes call it secondary octyl mercaptan or offer brand-specific versions aimed at elastomer or lubricant markets. Track all synonyms and catalog codes closely when ordering in bulk or comparing regional suppliers.

Safety & Operational Standards

Anyone handling 2-Octanethiol deals with hazards typical to thiol chemistry. The strong odor signals potential for both acute and long-term effects—skin and eye irritation, possible sensitization, and central nervous system effects if inhaled at higher concentrations. Proper PPE means gloves, goggles, and splash-resistant clothing always, as even brief direct contact can cause lingering smells and irritation. Strict ventilation, especially in synthesis labs or blending factories, keeps airborne concentrations below safety thresholds. Emergency response protocols should cover spill containment, rapid area evacuation, and thorough decontamination, given this compound’s tenacity. Storage in tightly sealed, properly labeled containers away from heat sources and incompatible oxidizers is a baseline requirement for long-term safety.

Application Area

Rubber processing uses 2-Octanethiol as a modifier and accelerator, improving crosslinking efficiency and elastomer properties. The lubricant sector values this compound for enhancing extreme-pressure performance in metalworking fluids. Some industrial flavor and fragrance manufacturers draw on its potent sulfur note in microdoses—relying on the nose-numbing pungency to build savory or roasted aromas. Electronics and surface science employ 2-Octanethiol for self-assembled monolayer production, tailoring gold surfaces for biosensor or microelectronic use. In each field, only tight dosing and process control keep positive results on track and minimize waste or side effects.

Research & Development

Emerging work in organic electronics leans heavily on thiol monolayers for building smart sensors, switches, and field-effect transistors. Chemists chase new reactions for specialty polymers and catalysis targeting greener, higher-yield pathways. Research institutions continue mapping the boundary between beneficial surfactant modifications and toxicity, using both lab tests and computational models. Surface chemistry with 2-Octanethiol has delivered functionalized nanoparticles, biocompatible coatings, and diagnostic platforms tough enough for clinical use. My conversations with polymer scientists hint at growing demand for these sulfur agents in tuning hydrophobicity and chemical resistance in wearable tech and packaging.

Toxicity Research

Toxicologists know well the double-edged nature of thiols. Even at relatively low airborne concentrations, 2-Octanethiol triggers headaches, nausea, and eye irritation—sometimes at parts-per-million levels. Prolonged exposure can sensitize skin or lungs, meaning that repeat contact drives up risks beyond what initial safety data reveal. Testing involves acute and chronic dosing in animal models, careful monitoring of workplace exposure, and ongoing updates to permissible limits. A history of incidents in rubber plants and flavoring facilities has led regulators to tighten permissible exposure thresholds and invest in better detection technologies. Working directly with this compound, the importance of scarves, fume hoods, and airtight containment never fades.

Future Prospects

2-Octanethiol stands ready for broader adoption wherever surface modification or specialty sulfur effects count. Green chemistry drives demand for milder, recyclable reagents—encouraging the search for bio-based or less toxic synthetic routes. Wearable electronics, next-generation gas sensors, and targeted drug-delivery all push for new uses of thiol-anchored surfaces and materials. Fine chemical production trends toward automation and improved traceability, holding manufacturers to ever higher standards of product purity and downstream safety. Today’s research points to expanded value across batteries, coatings, and catalysts, provided tight controls on exposure and environmental stewardship keep pace. Within the next decade, 2-Octanethiol could shift from a niche ingredient to a platform raw material for advanced manufacturing and green technology solutions.

A Strong Smell with Real Staying Power

2-Octanethiol stands out thanks to a sharp, lingering smell. I once caught a whiff in a lab, and the memory still sticks years later. Anyone who’s worked with sulfur-heavy chemicals remembers it. Industrial chemists rely on this compound not because they enjoy the scent, but because it offers chemical muscle for a few hard-to-solve problems.

Finding a Home in the Oil Industry

The oil and gas industry sits high on the list for 2-Octanethiol use. Refineries add this chemical to refined fuels like natural gas—not to make it better, but to make it safer. Natural gas has no odor, which creates a huge risk if there’s a leak. By blending in a bit of 2-Octanethiol or similar mercaptans, any leak becomes noticeable in an instant. Lives depend on this signal, as the strong scent cuts through distractions and warns people to act fast. Pipelines rely on this method all over the world.

Solving Stubborn Problems in Chemical Synthesis

Beyond the oilfield, research chemists look to 2-Octanethiol when they need a building block for creating new molecules. It’s useful for adding sulfur elements to organic compounds. This serves a niche but key role in pharmaceuticals and agrochemicals. While the average medicine cabinet doesn’t hold 2-Octanethiol, the synthetic pathways behind some drugs or crop-protecting chemicals might. A bit of added complexity from this compound can change the whole nature of a finished product.

A Tool for Scientists: Building Surfaces That Self-Assemble

Materials science, often hidden from public view, has seen a lot of progress from molecules like 2-Octanethiol. Researchers use it to help create “self-assembled monolayers”—thin films that stick to metal surfaces and reshape properties at the atomic level. This matters for electronics, sensors, and nanotechnology. I’ve met graduate students who spend months getting the thickness of these coatings just right. Their goal: surfaces that repel water, attract specific molecules, or control reactions in tiny spaces.

The Perils: Worker Safety and Environmental Questions

No chemical gives all benefits and no headaches. Heavy use of 2-Octanethiol means figuring out safe handling rules and keeping emissions to a minimum. Prolonged exposure can irritate skin and lungs, and spills lead to foul smells that take over whole neighborhoods. Regulations put clear limits on who can handle it, and in what volume. Working under the hood and with proper protective gear keeps people safe, but the worry over what escapes into the environment stays top-of-mind for plant managers.

Pushing for Safer Alternatives

Many groups want to use less toxic additives and improve odor detection for safety. New electronic sensors for leaks appear in the market, but nothing beats a nose for instant alert. The pressure for greener chemistry pushes companies to look for better substitutes or to engineer processes that need fewer hazardous ingredients. Some startups search for renewable surrogates, tapping into plant-based chemicals. These efforts can take years, yet they’re worth watching as public attitudes around chemical safety change.

The Bottom Line for Everyday Life

Few people ask what’s inside a sulfur-based odorizer, or if the molecule coating a microchip’s metal wiring started as a lab smelly as eggs. Yet, the safety of a gas line, the function of a solar panel, or a new cancer drug sometimes depends on these behind-the-scenes chemicals. Knowing more gives us power to ask industry leaders for transparency and encourage research into safer, smarter tools for the future.

Understanding 2-Octanethiol Starts with the Basics

2-Octanethiol doesn’t quickly roll off the tongue, yet the details behind its name tell an important story about how chemistry touches daily life. Many folks don’t get too excited about naming conventions in organic chemistry, but in this case, the rules provide more than trivia—they open the door to understanding what we deal with. The “octane” part shows the skeleton at play: eight carbon atoms chained together. “Thiol” means we’re not talking about your everyday hydrocarbon because it has a sulfur-hydrogen (-SH) group attached. The “2-” placement clarifies the sulfur connection: it hooks onto the second carbon. As a result, the chemical formula: C8H18S. Anyone who’s spent some time in a chemistry lab recognizes how each piece in this name matters.

What Makes This Molecule Useful?

Look at industries that use sulfur compounds—flavor, fragrance, and even fuel additives. 2-Octanethiol isn’t loud in the news, but up close, it plays its part. The molecule’s sulfur group gives it that distinctive, robust aroma sulfur organics are known for; think of it like a concentrated whiff of onion or garlic. This pungency isn’t just for shock value. It sets off reactions with metals, which can act as corrosion inhibitors. Some researchers use these chemicals as building blocks for more complex molecules, including pharmaceuticals and agricultural products.

Safety and Environmental Concerns Deserve Attention

2-Octanethiol delivers a strong scent for a reason—the compound’s potency walks hand-in-hand with its reactivity. People who handle it in laboratories know to rely on gloves, eye protection, and proper ventilation. Strong-smelling thiols have a way of announcing themselves and don’t just fade easily. Spills can linger for days, which makes quick response necessary. On a larger scale, improper disposal can cause harm to waterways and wildlife, as sulfur-containing compounds break down slowly and lead to long-term effects. That’s why companies involved in the transportation or storage of organic thiols invest in robust containment measures and emergency response drills.

What Can Be Done About Potential Problems?

Even though 2-Octanethiol serves important industrial functions, safer practices and innovative chemistry provide opportunities for improvement. Many researchers now focus on creating less hazardous alternatives or modifying existing molecules to limit environmental persistence. Regulatory agencies require clear labelling and documentation, which helps prevent mishandling. Training laboratory staff and workers—not just engineers—on spill management and first-aid remains crucial. Community outreach can also help. In residential areas near manufacturing plants, public safety officials often hold briefings so that residents know what to do if they smell sulfur in the air.

Looking Ahead

Tracking how chemicals like 2-Octanethiol fit into the world feels more important today than ever. Chemistry doesn’t stay inside textbooks. Every sulfur-tinged molecule carries a lesson. Dismissing it as just another formula misses the big picture: scientific literacy gives people room to ask smarter questions, challenge risky practices, and look for better answers. By understanding names, formulas, and what they mean in context, we all stack the odds for a cleaner, safer, genuinely smarter tomorrow.

Looking at 2-Octanethiol’s Reputation

2-Octanethiol isn’t the sort of chemical folks run into daily at the grocery store or in their backyard. This compound, known in technical circles as an alkanethiol, tends to show up in laboratories, chemical plants, and sometimes university classrooms. Most people wouldn’t recognize it by smell or look, but chemists often point out its strong, pungent odor—a trait shared with plenty of sulfur-based chemicals.

Direct Exposure: What Happens?

The question always shows up in discussions: is it hazardous or outright toxic? Based on my experience working around lab chemicals, most thiols get a reputation for being tricky and unpleasant if treated carelessly. 2-Octanethiol doesn’t buck that trend. Its fumes can irritate the eyes, nose, or throat. People report headaches and dizziness after breathing its vapors, and contact with skin or eyes leads to stinging and redness.

The Globally Harmonized System (GHS) classifies the compound as hazardous, mainly for its ability to cause serious eye and skin irritation. Research from the National Institute for Occupational Safety and Health points to acute effects rather than life-threatening consequences from brief exposure. Still, spill some on unprotected skin, and you’ll want a quick rinse under cold water.

Real Dangers: Accidents and Longer Exposure

Stories from chemical safety briefings tell the real story—2-Octanethiol can hurt you if ignored. I’ve seen colleagues get light-headed after exposure in a poorly ventilated workspace. The compound’s vapor is heavier than air, so it collects low to the ground and sticks around, especially in closed-off spots.

Animal studies give more context. Long-term exposure in rats led to organ changes and mild signs of toxicity, but those cases used doses higher than what a human would see outside a laboratory. There’s no widespread record of 2-octanethiol causing cancer or chronic diseases in humans, but regulatory agencies like the EPA stay on alert for newer findings.

How Much Is Too Much?

Industry organizations set recommended limits for workplace exposure, often measured in parts per million. Workers using this chemical indoors need eye protection, gloves, and plenty of fresh air. Anyone storing or transporting 2-Octanethiol should check tanks and packaging materials, since sulfur compounds can corrode certain metals faster. Standard spill kits and ventilation systems keep minor accidents from turning into emergencies.

Safer Practices for Everyone

Training makes all the difference. Companies using 2-Octanethiol owe employees up-to-date safety sheets and emergency procedures that actually work. I’ve seen less-experienced staff shrug off the importance of personal protective equipment, only to regret their choice after an eye-watering splash of thiol in the workspace.

On a community level, local governments and environmental groups track chemical shipments and storage. Even though 2-octanethiol rarely leaks out into neighborhoods, responsible waste disposal and accident reporting keeps people safe and builds trust. Anyone using unfamiliar materials owes their coworkers and neighbors an extra level of caution.

To sum up the matter: 2-Octanethiol won’t kill you in a whiff, but it packs enough punch to demand respect. Following basic rules, using safety equipment, and keeping good training put most risks in check.

Why Storage Matters for 2-Octanethiol

Anyone who’s worked with chemicals knows that ignoring storage basics is asking for trouble. 2-Octanethiol stands out thanks to its strong odor and reactive nature. I’ve spent enough time in labs to recognize the headache this chemical brings if left unchecked—literally and figuratively. Sulfur compounds like this have a habit of generating complaints if they start leaking out of containers. Beyond the nuisance, there’s a safety concern too: fumes, accidental contact, and the risk of fire.

Conditions That Actually Work

My experience shows that tight control over temperature keeps volatile chemicals stable. 2-Octanethiol should not get hot. Warm temperatures cause pressure to build inside sealed glass or metal, increasing the odds of leaks or ruptures. Storing it at room temperature—ideally under 25°C—keeps containers intact and the air safe to breathe.

Direct sunlight messes with chemical stability. It pays to use amber bottles or keep the containers in cabinets set far from windows or heat vents. Ultraviolet rays can degrade thiols, changing their profile and, at worst, triggering weird reactions no one accounted for. Best practice in teaching labs and industry means keeping these bottles out of sight, in dry, shaded spaces with nothing above them that might fall or spill.

Humidity’s another silent enemy. Moisture corrodes metal and weakens seals. While plastic or glass with decent caps solves most issues, silica gel packs can help if the building sweats during summer. The chemical’s vapors easily escape if the lid isn’t on tight, so check that caps screw on like they’re supposed to.

Ventilation and Spill Control

I once watched a bottle of thiol get dropped. The reek filled our floor in minutes. Even without spills, low concentrations in the air alert anyone nearby. Good ventilation isn’t just for comfort—it’s for real safety. Storing bottles in well-ventilated rooms, away from spots used for eating or drinking, cuts risks. Fume hoods work best for dispensing, especially in research labs.

Planning for spills hasn’t always been a priority, but after years in labs, I’ve learned to trust chemical trays. Storing 2-octanethiol inside a spill-resistant secondary container makes cleanup quick. No one wants to discover a leaking bottle with only paper towels on hand. Absorbent mats or granules for sulfur compounds help soak it up, while a sealable waste can keeps the used material safe until disposal.

Security and Compatibility

Locking up bottles limits access and reduces theft or tampering. I’ve never heard of anyone wanting to steal a thiol for thrills, but the rules apply. Only trained folks should handle this stuff, especially because skin or eye contact can burn and the vapor isn’t much nicer. Keeping logs of who takes what, and checking containers now and then, creates a habit of responsibility.

Never put thiols next to oxidizers. Combustion risks jump when incompatible chemicals sit side by side. It’s wise to sort shelving by chemical family, labeling shelves, and separating acids, bases, peroxides, and anything that reacts badly with sulfides. Regular checks for corrosion and leaks help head off bigger problems.

Trusting What Works, Not Shortcuts

Safety protocols often feel like extra paperwork, until something goes wrong. Following real-world storage tips for 2-octanethiol—cool, dry, secure, and ventilated—keeps people safe, pockets protected, and workplaces running smoothly. People count on you to get storage right, not just for the sake of rules, but because reputation and health depend on it.

The Real-World Value of Reliable Purity Data

Ask any chemist who’s wrestled with unpredictable reactions: reliable purity matters. 2-Octanethiol crops up in the flavor and fragrance sphere, and in specialty chemical labs, where a misplaced impurity can spoil a batch or give false results. Suppliers often tout “purity over 98%.” For research or critical formulation, folks usually chase the highest grade, but I’ve seen how even tiny impurities can throw off sensitive processes. Unwanted side products aren’t just a headache. They can send projects back to square one, wasting both material and man hours.

I remember once working on a project involving sulfur compounds. A single misjudgment about purity forced us through weeks of tedious purification and data rework. The costs in time and morale were real. Relying on a reputable supplier who stands behind their Certificate of Analysis saves hassle. That’s why purity specs above 98% hold actual street value for teams needing precision.

CAS Numbers: Not Just for Paperwork

Every chemical gets a CAS number. 2-Octanethiol calls 111-88-6 its own. Sounds dull, but every person I know who’s ordered specialty organics learns quick: always check the CAS. Trade names change, labels get smudged, but the CAS sticks. If you don’t pay attention, it’s easy to wind up with something that behaves differently because a supplier switched naming conventions or started using a synonym. All it takes is one wrong number to derail months of progress or cause a shipment to be stopped by customs. That single CAS number becomes a kind of passport at every step, from quoting to customs clearance, lab prep to reporting. The details ground the chemistry in real life, not just catalogs.

Why Purity and Identification Get Ignored—And Why That’s a Problem

Too often, folks in smaller labs or startups might look at the bottom line and opt for a cheaper, lower-purity source. On paper, the difference between 96% and 99% sounds small. But as someone who’s watched side reactions destroy product yield, I can tell you: that’s a shortcut that bites back. I’ve witnessed entire research programs set back over minor contaminants. For flavor and fragrance developers, off-notes from stray compounds put brand reputation on the line. In academia, repeating failed experiments chips away at trust in published results. These real-world pains underscore why purity matters beyond just price sheets.

Steps Toward Better Practices

Suppliers have a role. They need to be up-front about both typical and minimum purities, not just flashy marketing stats. Certificates of Analysis should list actual test results rather than vague ranges. Laboratories ought to double-check the CAS before integrating new chemicals, even for routine orders. It helps to build long-term relationships with trusted suppliers who welcome scrutiny and can explain their quality controls. Investing in in-house verification equipment pays back, especially when the margin for error is slim.

Straight talk: substances like 2-Octanethiol should only enter production or research after careful confirmation of both purity and proper identification. The time spent hunting down real Certificates of Analysis and cross-checking CAS numbers saves aggravation and resources in the long run. Anyone ignoring these basics risks repeating the errors I’ve seen play out too many times.

Final Thoughts

In the world of specialty chemicals, details build trust. Purity above 98% and the correct CAS number—111-88-6—aren’t just technical points. They decide whether a project gets finished on time, a research paper stands up to scrutiny, or a product line keeps its reputation intact. That kind of reliability shapes careers and companies, not just lab notebooks.

| Names | |

| Preferred IUPAC name | Octane-2-thiol |

| Other names |

1-Methylheptanethiol

n-Octyl mercaptan Octyl mercaptan n-Octanethiol n-C8H17SH |

| Pronunciation | /tuː-əʊkˈteɪn.θaɪ.ɒl/ |

| Identifiers | |

| CAS Number | 111-88-6 |

| Beilstein Reference | 83255 |

| ChEBI | CHEBI:38790 |

| ChEMBL | CHEMBL383921 |

| ChemSpider | 77195 |

| DrugBank | DB14007 |

| ECHA InfoCard | ECHA InfoCard: 100.007.883 |

| EC Number | 208-754-4 |

| Gmelin Reference | 74074 |

| KEGG | C18112 |

| MeSH | D013004 |

| PubChem CID | 15614 |

| RTECS number | RG0350000 |

| UNII | 82R374E53K |

| UN number | UN2668 |

| Properties | |

| Chemical formula | C8H18S |

| Molar mass | 146.29 g/mol |

| Appearance | Colorless to yellow liquid |

| Odor | Unpleasant, garlic-like |

| Density | 0.834 g/mL at 25 °C |

| Solubility in water | Insoluble |

| log P | 3.83 |

| Vapor pressure | 0.16 mmHg (25°C) |

| Acidity (pKa) | 10.6 |

| Basicity (pKb) | pKb ≈ 3.5 |

| Magnetic susceptibility (χ) | -73.0e-6 cm³/mol |

| Refractive index (nD) | n20/D 1.444 |

| Viscosity | 2.1 mPa·s (20 °C) |

| Dipole moment | 3.05 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 362.96 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -222.5 kJ·mol⁻¹ |

| Std enthalpy of combustion (ΔcH⦵298) | -5155.7 kJ/mol |

| Hazards | |

| GHS labelling | GHS02, GHS05, GHS06, GHS08 |

| Pictograms | GHS06,GHS07,GHS08 |

| Signal word | Warning |

| Hazard statements | H226, H302, H315, H317, H319, H335, H411 |

| Precautionary statements | P210, P233, P240, P241, P242, P243, P261, P264, P270, P271, P273, P280, P301+P310, P302+P352, P304+P340, P305+P351+P338, P308+P311, P312, P321, P330, P362+P364, P363, P370+P378, P403+P235, P405, P501 |

| NFPA 704 (fire diamond) | 2-2-2-W |

| Flash point | 67 °C |

| Autoignition temperature | 240 °C |

| Explosive limits | Explosive limits: 0.9% - 6.5% |

| Lethal dose or concentration | LD50 (oral, rat): 820 mg/kg |

| LD50 (median dose) | LD50 (median dose): Oral rat 820 mg/kg |

| NIOSH | TIQ000 |

| PEL (Permissible) | Not established |

| REL (Recommended) | REL (Recommended Exposure Limit) for 2-Octanethiol is: "0.5 ppm (2 mg/m³) TWA |

| IDLH (Immediate danger) | IDLH: 100 ppm |

| Related compounds | |

| Related compounds |

1-Octanethiol

2-Nonanethiol 2-Heptanethiol |