Isopropyl Mercaptan: A Deep Dive into Its Past, Uses, and Future

Historical Development

The story of isopropyl mercaptan stretches back to the rise of organic chemistry in the early 1900s. Early chemists, always on the hunt to understand peculiar smells and stubborn contaminants in crude oil, stumbled onto organosulfur compounds like isopropyl mercaptan. In those days, these molecules were curiosities from refinery columns, yet researchers saw their unusual power. On my lab bench, that skunk-like aroma meant sulfur was in the mix—a signal as old as the field. Over the decades, methods for isolating and handling these sharp-smelling substances matured with the perfume and gas industries. Refineries kept flags handy to warn about releases, but they worked to use mercaptans wisely rather than only treat them as nuisances. The record of patents and trade names, especially from the 1940s, tells a tale of discovery powered by tenacity and a nose for both opportunity and risk.

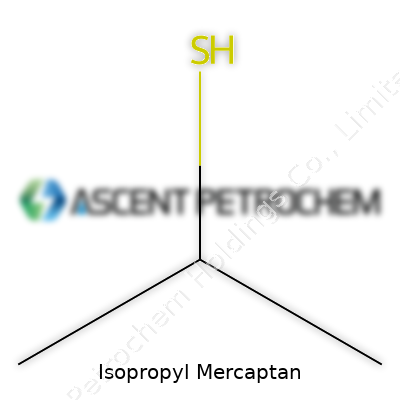

Product Overview

Isopropyl mercaptan, known to chemists as 2-propanethiol or propan-2-thiol, stands out for its piercing odor and reactivity. This colorless to pale yellow liquid finds its way into the world mostly as a warning agent, thanks to its truly powerful stench. Manufacturers often rely on it when adding odor to natural gas, which by itself doesn’t smell. The chemical hooks in tight to many types of organic matter, so it lingers and travels easily, making it a favorite for leak detection. I have seen its distinctive profile pop up in chemical plants and petroleum operations where the stakes for quick detection are high.

Physical & Chemical Properties

Isopropyl mercaptan bears the chemical formula C3H8S. It boils near 59°C and freezes around -117°C, much nearer to familiar temperatures than heavier relatives. The density hits about 0.79 g/cm³ at room temp. The molecule mixes sparingly with water but dissolves in many typical organic solvents. Its volatility and lipophilic nature make safety considerations essential. It’s flammable, with a flash point lurking around -18°C. One whiff will convince most that it remains a powerful olfactory trigger, which comes from the sulfur atom snuggled inside its structure. Experience in handling pure samples left my hands and equipment reeking for days—one drop lets the entire building know what you’re working on.

Technical Specifications & Labeling

Industrial suppliers tend to offer isopropyl mercaptan in steel cylinders or sealed drums, each emblazoned with hazard diamonds and sulfur warning pictograms. Standard purity for odorizing use settles at 95% or higher, but contamination with other mercaptans and sulfides can alter the safety profile immediately. Labels point to the UN number 2347, hazard class 3 (flammable liquid) and class 6.1 (toxic), and regulatory information straight from OSHA and REACH databases. Firms shipping the stuff train staff to follow right-to-know laws and keep detailed safety data sheets close at hand. Regulations insist on thorough traceability, which becomes especially clear after any spill, leak, or worker complaint.

Preparation Method

Isopropyl mercaptan production hinges on nucleophilic substitution chemistry: treat isopropanol or isopropyl halides (like isopropyl chloride) with sodium hydrosulfide under strictly anhydrous, oxygen-free conditions. The reaction calls for an inert atmosphere, since exposure to air risks both side reactions and runaway stench. Modern plants amp up yields by recycling solvents and scrubbing by-products. Homemade attempts to whip up a mercaptan only produce chaos—these chemicals want the lab’s respect, not shortcuts. Continuous flow reactors and better catalysts have cut down energy demands in the last two decades.

Chemical Reactions & Modifications

The sulfur-hydrogen bond at the core of isopropyl mercaptan opens doors for complex organic transformations. The thiol group swaps places in radical reactions or couples up with metal catalysts to make new sulfur heterocycles for pharmaceuticals. Oxidation can turn the molecule into disulfides, which sometimes have value as specialty additives or chemical intermediates. I have personally had to neutralize residues with bleach solutions—a step that liberates a choking sulfur cloud if handled wrong. On the bright side, the compound’s reactivity makes it a useful starting point in research labs for designing both flavor agents and corrosion inhibitors.

Synonyms & Product Names

Across scientific literature and trade channels, isopropyl mercaptan appears under several labels: 2-propanethiol, propan-2-thiol, isopropanethiol, and the catchy trade name IPM. Less formal sources call it “gas odorant” or simply “mercaptan.” In safety planning, these synonyms feed directly into labeling and spill procedures. Chemistry textbooks flag all the isomers of mercaptan, but field technicians fixate on the distinct stench and the three-carbon backbone that sets it apart from methyl or ethyl mercaptan.

Safety & Operational Standards

Handling isopropyl mercaptan means investing in containment and ventilation systems, not just relying on good intentions. The chemical irritates eyes and lungs and acts as a moderate skin sensitizer. A splash can linger in a workspace for days if not cleaned promptly. Most facilities require full PPE, chemical gloves, and vapor masks. Storage demands cool, dry space, away from oxidizers and open flames. Emergency plans must include spill kits, fire extinguishers, and immediate access to fresh air. OSHA sets workplace exposure limits, and plant managers enforce them strictly—especially after complaints about leaks or headaches. From my work in hazardous materials training, few words clear a room faster than “mercaptan spill.”

Application Area

Practical use for isopropyl mercaptan revolves around leak detection in fuel distribution and liquefied gases. Adding just a sliver to natural gas pipelines enables rapid, nose-based identification of leaks. This early warning system has saved countless lives since the 1930s. Certain chemical syntheses turn to this compound as a starting material for making agricultural chemicals or flavoring agents—though exact concentrations get tightly regulated. Some researchers use it to calibrate odor-detection equipment or to study the thresholds of human olfaction. It can even surface in environmental monitoring labs looking for sulfur contamination. Every application returns to its unmistakable odor and rapid dispersion, traits both a blessing and curse.

Research & Development

Chemists digging deeper into isopropyl mercaptan have found ways to tweak its reactivity, tone down its scent, and make derivatives with lower toxicity for food and fragrance industries. Recent years have seen work on odor masking and targeted decomposition, since accidental releases cause costly plant evacuations and public complaints. Research grants support projects on selective oxidation and the search for biodegradable substitutes. Data mining through patent records points to dozens of utility models registered in Europe and Asia, all seeking better control or cleaner production routes. The greatest leaps remain in catalysis and odor remediation, both of which cut costs for chemical plants and environmental operators.

Toxicity Research

Animal studies and workplace surveillance show that isopropyl mercaptan causes throat, eye, and lung irritation well below levels that threaten life. Severe exposure sometimes brings headaches and nausea. Chronic low-level inhalation, like that experienced by refinery workers before modern airflow controls, has linked to mild symptoms. Regulatory bodies like NIOSH and ACGIH set exposure thresholds far lower than the stench threshold for this reason. In high doses, the chemical affects the nervous system and can act as a narcotic. Luckily, sensitive noses usually detect leaks at concentrations hundreds of times lower than those associated with harm. Ongoing toxicology projects continue, taking into account long-term environmental breakdown, groundwater migration, and wildlife exposure.

Future Prospects

The role of isopropyl mercaptan stretches beyond its current spot in gas safety and into emerging fields. Green chemistry circles look for ways to repurpose thiols as controlled-release agents in fertilizer and pharmaceuticals. Advances in filter technologies raise hopes for odorless alternatives that could do the same safety jobs with less disruption. Policy changes in the energy sector may force companies to push for more biodegradable or less volatile warning agents. I have seen students aiming at biotechnological production routes, blending synthetic biology and waste valorization. The story of isopropyl mercaptan, with its balance of utility and hazard, leads researchers to rethink chemical stewardship in a more connected, odor-sensitive world.

The Nose Knows: Why We Add Odor to Gas

I’ve always thought the story behind “rotten egg smell” in propane and natural gas was more than a quirky fact. Real danger lurks around odorless gases. Imagine discovering a gas leak in your home only after it’s too late. Lives have been lost that way. The answer to this safety risk: a fiercely pungent chemical called isopropyl mercaptan.

Keeping Homes Safe

Isopropyl mercaptan, a sulfur compound, gives off a smell you can’t miss. Think skunk spray, heavily boiled cabbage, even decaying vegetables. Energy and chemical companies use this chemical as an added warning sign. Natural gas by itself can sneak into your lungs unnoticed. A nose-punching odor puts everyone on high alert. Catching a suspicious smell pushes folks to shut off the stove, open windows, or phone the fire department. For me, the strong scent whenever the pilot light goes out serves as a vital reminder: the system works because of this simple additive.

Beyond Households—Industrial Use

Beyond kitchens and water heaters, isopropyl mercaptan steps into other corners of industry. Some refineries rely on it to track leaks in gas pipelines far from homes and offices. Without a strong, distinct warning agent, leaks would go unnoticed until much greater harm had already unfolded.

How Does It Actually Work?

The secret behind mercaptans like this isn’t just the strength of the smell. It’s the way the human nose can sense them at concentrations as low as one part per billion. Most folks can catch a whiff even if the chemical floats in the air at levels far from dangerous. That early signal gives precious time to fix a leak before gas explodes or someone falls ill.

Environmental and Health Concerns

Some people worry about safety when chemicals get tossed into the mix. In my experience, the upsides win. Isopropyl mercaptan doesn't hang around long once it escapes into open air. Sunlight and bacteria break it down pretty quickly. Long-term buildup isn’t likely in places where people and animals live. That said, anyone working daily with mercaptans needs decent ventilation and proper gear. Prolonged exposure at high levels may cause headaches or nausea. Gas industry regulations help reduce that risk by setting safe limits and storage guidelines.

Room for Improvement

Avoiding leaks altogether tops every engineer’s wish list. Yet pipes wear out, screws loosen, and accidents happen. Pairing advanced sensors with old-school mercaptan odor can offer multiple layers of safety. Smart devices today can trip shutoff valves or trigger alarms, adding insurance in case a nose misses the warning. Electric and renewable energy will someday cut back on our reliance on gas, but for now, adding odorants like isopropyl mercaptan keeps millions of people out of harm’s way.

The Takeaway

Sometimes the best tools save lives by being almost invisible—except for the stench. That’s what makes isopropyl mercaptan important. It’s not glamorous, it’s not trendy, and it doesn’t make headlines unless something goes wrong. Keeping people safe often means using what works, no matter how strong it smells.

Why Isopropyl Mercaptan Deserves Extra Caution

Anyone working around chemical storage tanks in industrial sites knows the name Isopropyl Mercaptan. That sharp, skunky odor hits you before you even check the label. It doesn’t take expert training to realize this stuff means business. Used as an odorant in gas pipelines, its clinging scent flags leaks that could otherwise spell disaster for workers or neighborhoods. The thing is, detecting it doesn’t guarantee you’re handling it safely.

Personal Experience Shapes My Caution

Years in chemical storage have shown me: one careless moment around volatile compounds can lead to long shifts in the ER—or worse. With Isopropyl Mercaptan, gloves, goggles, and face shields aren’t extras, they’re as vital as your morning coffee. Splash this onto bare skin and you’ll deal with rashes. Inhaling it gives burning throats and watery eyes. The bodily reaction shouts one message—respect the boundaries.

Straightforward Safety Starts With Good Gear

Standard-issue nitrile gloves and goggles get you covered against splashes. I always go for flame-resistant lab coats and closed-toe boots. This chemical catches fire almost faster than gasoline vapors. Left to evaporate, those vapors collect low and travel across shop floors. Sparks, even from a faulty power strip, set off blazes that move in seconds. Having explosion-proof fans and practicing strict no-smoking rules isn’t just rule-following, it makes sure everyone clocks out unharmed.

Ventilation: The Unsung Hero

Ventilation keeps air safe and noses clear. I’ve worked in cramped storage rooms where one open bottle had folks running for fresh air. Fume hoods and well-maintained exhaust fans need to run at all times. We keep detection meters handy, which give early warning if levels spike. Relying only on your senses invites accidents; digital meters back up your nose’s limits.

Emergency Preparedness: Training Pays Off

Spill drills never get old. We train new hires hard—if Isopropyl Mercaptan makes its way onto clothes or hands, water and soap come before any lunch break. Any contact deserves a trip to on-site first aid. Knowing how to use eye flush stations and showers means the difference between a minor scare and a hospital stay. Site supervisors map clear evacuation routes and keep fire extinguishers ready. These steps stop confusion when tensions rise.

Safe Storage Stops Trouble Before It Starts

I never stack Isopropyl Mercaptan next to oxidizers or acids. Fire hazards multiply fast. Leak-proof, labeled containers with tight seals find their home in cool, well-ventilated areas. Even a small drip can stink up an entire wing. We track inventories and log checks so nobody stumbles upon an unmarked container. Nothing replaces regular audits and strong labeling habits—label every container and train every new face in the shop, without exception.

Solutions That Strengthen Confidence

Relying on shared knowledge and real training builds a confident team. Clear communication, posted procedures, and an environment that rewards speaking up about near-misses keep everyone sharp. Upgrading detection tech and keeping open lines with local first responders builds a layer of trust that pays back in an emergency. Sharing lessons from incidents—without blaming—ushers in real improvements. Over time, respect for Isopropyl Mercaptan grows into second nature for anyone on site.

The Nitty-Gritty of Isopropyl Mercaptan

Step into any lab or chemical plant and mention isopropyl mercaptan. The first thing that comes up? That unforgettable, punch-you-in-the-nose odor. The molecule packs a skunky, sulfurous smell that people can detect at incredibly low concentrations, even below a single part per billion. It doesn’t take a trained nose to find a leak when this stuff is involved. There’s a good reason for that—companies blend it into propane as a warning sign to catch leaks before something dangerous happens.

Getting Personal with Isopropyl Mercaptan’s Structure

This chemical falls under the family of thiols. Stick a sulfur atom onto a hydrocarbon chain—here, isopropyl—and the odor gets wild in a hurry. The molecular formula, C3H8S, means three carbons, eight hydrogens, and one sulfur. Colorless as a liquid, it can look harmless. It boils at around 59°C (138°F). Spill a little on the floor and it vanishes into the air faster than you might think. No dramatic fountains of steam, just an instant atmosphere of rotten eggs.

Physical Characteristics That Stand Out

Pick up a bottle of isopropyl mercaptan, and it pours like water. Less dense than water, it floats if you mix the two together. Since it evaporates quickly above room temperature, good ventilation isn’t a suggestion—it’s required. This volatility helps with gas leak detection, since a single drop can fill a large space with a strong warning smell. It dissolves well in organic solvents, but not in water. Get it on your skin, and the oily residue clings, making cleanup tedious. Soap alone just won't do it; the smell latches on.

Chemical Reactivity Makes It Useful and Tricky

The sulfur atom in mercaptans isn’t shy about bonding with metals and oxidizing agents. That comes in handy for industrial chemistry. Looking for a way to synthesize other chemicals or get rid of unwanted metal ions? Isopropyl mercaptan reacts fast and turns into disulfide when it runs into oxidizers. This tendency means it doesn't stick around too long out in the open. If it finds chlorine, it forms isopropyl sulfonyl chloride, which then hops into different areas like pharmaceuticals and plastics.

The Human Factor and Safety Concerns

No sensible chemist works with isopropyl mercaptan without some serious protection. That vapor isn’t just an annoyance; inhaling too much can cause headaches and nausea. Touching it leads to skin irritation. In my experience, once the smell gets onto your clothes or shoes, it hangs around long after you leave. Engineers working in propane or natural gas know that without the right gear—a good fume hood, gloves, goggles—the job gets risky fast.

Finding the Middle Path: Handling and Solutions

Keeping this compound under control takes more than just airing out a room. Gas detectors help keep workers safe. Strong local exhaust systems keep the smell—and its effects—at bay. Storage in tightly sealed containers limits accidental exposure. Spills need immediate cleanup, which doesn’t just mean mopping; it’s often about neutralizing the thiol with bleach or peroxide. Training crews on these steps protects more than just noses; it keeps jobsites and neighborhoods safe.

Why It’s Worth the Trouble

Despite the challenges, isopropyl mercaptan’s combination of high volatility and intense smell saves lives. Think about the times when natural gas leaks are caught before turning deadly. That isn’t luck; it’s deliberate chemistry. The same properties that make it so obnoxious also make it one of the unsung heroes of public safety. Mastering its use pays off in peace of mind for workers, companies, and communities.

Smell, Risk, and Storage

Anyone who's been around industrial chemicals knows Isopropyl Mercaptan by its reputation long before they spot its container. It’s got that unmistakable stench you never want let loose in a workspace. That odor isn’t just a nuisance—it signals danger. This liquid isn't just pungent; it’s highly flammable, volatile, and can cause real harm if handled carelessly. Understanding the stakes isn't just chemistry trivia—it’s common sense for anyone who’s worked through a chemical spill or evacuation.

Fire Hazards and Temperature

One of the first things you notice working with Isopropyl Mercaptan: fire loves this stuff. You can't store it near electrical panels, open flames, or heat-generating sources. Factories keep it in cool, well-ventilated storage rooms. Keeping the temperature down and away from direct sunlight helps keep both workers and property safe. Too much heat sends vapor into the air and that can trigger not just alarms but real emergencies. In the shops I've worked, alarms and exhaust fans aren’t just luxury—management installs them near every flammables storage unit.

Container Choice and Labeling

Companies lean on steel drums or approved chemical containers with airtight seals. These containers cut evaporation and leaks. Leaky caps turn a piece of equipment storage into a toxic zone overnight. That’s why teams check seals every time they move or open a drum. Labels need to spell out the content, hazard pictograms, and emergency instructions—plain and simple, so there’s zero guesswork. In one job, we used color-coded tags for fast emergency response, shaving critical minutes off reaction time.

Ventilation and Handling

Good ventilation isn’t just a “nice to have.” I've seen places run extra ducting just to guarantee no buildup of fumes, even during off-hours. Whenever someone draws product out of a drum, local exhaust and fume hoods pull vapors away from their face. The risk isn’t just in day-to-day work; cleaning up minor spills can create dangerous concentrations, especially if you're working without a mask. So, proper filters and respirators stay close by, and every worker gets trained in fast, safe cleanup.

Inventory Control and Monitoring

Letting chemical stocks pile up in neglected corners invites leaks, fire hazards, or contamination. Inventory logs matter. I’ve learned to trust systems that require sign-out and weekly checks. Automation helps: some companies install electronic sensors and alarms for temperature spikes or leaks. Those alerts have stopped more than one small problem from turning much worse.

Alternatives and Safer Practices

Some teams investigate substitutes where possible, especially if ventilation or fire-rated storage isn’t up to par. Until safer options find their way into mainstream supply chains, vigilance matters more than anything. Staff training needs regular updates. Dummy drills where someone acts out exposure—then scores of workers walk through the exact steps—stick with a team longer than any written procedure does.

Responsibility and Outcomes

A little neglect with Isopropyl Mercaptan magnifies quickly. Open containers and blocked vents compound risk in ways safety manuals describe, but nothing compares to cleaning the aftermath yourself. Smart teams build routines—double-checking seals, running sensors, keeping the area neat, replacing old signage—because facing the risk unprepared can change lives in minutes.

A Sharp Smell with Serious Consequences

Anyone who’s worked around gas, oil, or certain industrial sites knows the unforgettable odor of isopropyl mercaptan. That rotten egg or rank cabbage smell hits hard, warning noses long before the chemical reaches hazardous levels. It’s in products and processes everywhere—used as a warning agent in natural gas, a chemical intermediate, and sometimes in specialty solvents. But once you move past the stench, bigger problems come into focus.

Hazards: The Science and Real-Life Impact

This stuff isn’t just offensive—it hurts. Breathers exposed to high vapor concentrations can wind up with burning eyes, headaches, and nausea. Mucous membranes get irritated fast, so nosebleeds, sore throat, and coughing follow close behind. In certain industrial accidents, people have reported dizziness or even confusion—proof that the nervous system doesn’t like this compound. Animal studies back this up, showing signs of toxicity at levels just a little higher than what humans might meet in a bad spill or leak.

The skin won’t escape, either. Handle isopropyl mercaptan without gloves or proper gear, and it causes redness, pain, and sometimes blistering. Contact over a longer period opens the door for dermatitis, an itchy, persistent rash that disrupts daily life. Even a splash in the eye turns painful fast, risking lasting damage.

Airborne Risks: Why Ventilation Matters

Many exposures happen before anyone notices. Tight indoor spaces like poorly ventilated storage or laboratory rooms become a trap. The chemical lingers. Indoors, vapors build up, especially during spills, maintenance work, or transfer between containers. Indoor air monitoring doesn’t always catch the spikes in time, which is why people end up learning the hard way with sore throats and headaches after a day’s work.

Outside the workplace, incidents along pipelines or near tank farms spark urgent evacuations. Community exposure episodes have left neighborhoods scrambling—doctors’ offices fill up with folks complaining of eye burning, coughs, or worse. Some risk groups, including children, older adults, and people with asthma, feel the effects fastest.

Prevention: Learning to Work Smarter

Ignoring the odor never pays off. Regular safety briefings and working with real-time detectors cut through complacency. Bright warning signs at storage sites help keep everyone on their toes. For the people handling isopropyl mercaptan every day, those heavy-duty gloves and goggles save skin and sight more than once each year.

Local exhaust ventilation, fans, and proper handling procedures mean less vapor in the air. Nobody should work alone with this chemical. Teams matter—someone else spots a spill or stuck valve when a solo worker might miss it. Medical staff well-versed in chemical hazard treatment prepare clinics for the odd surge after an accident.

If a community sits near industrial sites, open communication makes a world of difference. Easy-to-understand notifications, quick response plans, and community outreach events build knowledge before disaster strikes. It’s the simple steps—clear safety rules, honest incident reporting, and ongoing attention to detail—that protect health every day.

Everyday Choices, Lasting Health

By staying alert and leaning into proven safety tools, workers and residents keep themselves far from unnecessary harm. Real investment in training and equipment pays off. Inhaling or touching isopropyl mercaptan isn’t an everyday risk most people look for, but it’s one too many have learned to respect the hard way.

| Names | |

| Preferred IUPAC name | propan-2-thiol |

| Other names |

2-Propanethiol

Isopropyl thiol Propane-2-thiol sec-Propyl mercaptan |

| Pronunciation | /ˌaɪ.səˈproʊ.pɪl mɛrˈkæp.tæn/ |

| Identifiers | |

| CAS Number | 75-33-2 |

| 3D model (JSmol) | `Isopropyl Mercaptan JSmol 3D model string:` ``` CSCC ``` |

| Beilstein Reference | 1209287 |

| ChEBI | CHEBI:37131 |

| ChEMBL | CHEMBL16840 |

| ChemSpider | 10423 |

| DrugBank | DB11309 |

| ECHA InfoCard | 100.006.323 |

| EC Number | 200-309-2 |

| Gmelin Reference | Gmelin Reference: 8786 |

| KEGG | C08298 |

| MeSH | D010090 |

| PubChem CID | 15684 |

| RTECS number | NI5950000 |

| UNII | 2H6X5P4EUC |

| UN number | UN2347 |

| CompTox Dashboard (EPA) | DJ3FFC5UQM |

| Properties | |

| Chemical formula | C3H8S |

| Molar mass | 76.16 g/mol |

| Appearance | Colorless liquid with a strong, disagreeable odor |

| Odor | unpleasant, skunk-like |

| Density | 0.794 g/mL at 25 °C |

| Solubility in water | slightly soluble |

| log P | 1.98 |

| Vapor pressure | 40 mmHg (20°C) |

| Acidity (pKa) | 10.7 |

| Basicity (pKb) | 3.75 |

| Magnetic susceptibility (χ) | -64.0 × 10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.442 |

| Viscosity | 0.476 mPa·s (at 20°C) |

| Dipole moment | 1.56 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 197.6 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | –95.3 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -2147 kJ/mol |

| Hazards | |

| GHS labelling | GHS02, GHS06, GHS07, GHS08, GHS09 |

| Pictograms | GHS02,GHS06 |

| Signal word | Danger |

| Hazard statements | H225, H301, H311, H331, H315, H319, H335, H400 |

| Precautionary statements | P210, P261, P273, P302+P352, P304+P340, P305+P351+P338, P312, P332+P313, P362+P364, P370+P378, P403+P235 |

| NFPA 704 (fire diamond) | 2-4-2-UNK |

| Autoignition temperature | ~380 °C |

| Explosive limits | 2% - 18% |

| Lethal dose or concentration | LD50 oral rat 179 mg/kg |

| LD50 (median dose) | LD50 (median dose): 179 mg/kg (rat, oral) |

| NIOSH | RN140 |

| PEL (Permissible) | PEL: 0.5 ppm |

| REL (Recommended) | 0.5 ppm |

| IDLH (Immediate danger) | IDLH: 500 ppm |

| Related compounds | |

| Related compounds |

Methanethiol

Ethanethiol n-Propyl mercaptan tert-Butyl mercaptan Dimethyl sulfide Diethyl sulfide |