Sec-Butyl Mercaptan: A Comprehensive Commentary

Historical Development

Sec-butyl mercaptan holds a curious place in the history of organic chemistry. Early chemists set their sights on sulfur-containing compounds because of their pungent odors, reactivity, and the way they behave in chemical reactions. Interest picked up in the mid-20th century when uses emerged in the oil and gas industry, particularly for leak detection due to sec-butyl mercaptan's recognizable scent. The chemical made its leap from a laboratory curiosity to a practical tool as industrial-scale synthesis methods became widely available. The journey mirrors the growth of applied chemistry across the board: researchers driven by practical applications, production gradually picking up pace, and regulatory scrutiny following close behind.

Product Overview

Sec-butyl mercaptan comes across as an organosulfur compound with a strong, characteristic odor. Many recognize the distinct sulfurous smell even at low concentrations—there’s no mistaking it. The compound gets bottled up in steel drums, glass containers with tight seals, or polymer-lined vessels to prevent vapor leaks. Commercial grades often reach above 98% purity, with color ranging from clear to straw yellow depending on storage and handling. Laboratories, industrial leak-detection services, and chemical research outfits make regular use of this compound because it’s reliable, recognizable, and reacts in predictable ways.

Physical & Chemical Properties

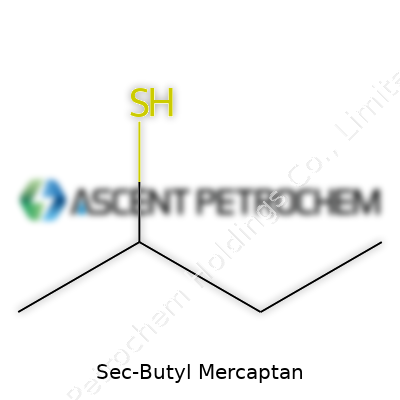

Sec-butyl mercaptan exists as a volatile liquid at room temperature. The boiling point hovers around 97 °C, and freezing occurs near -116 °C. The stuff evaporates quickly, thanks to a low vapor pressure, filling closed workspaces with its signature reek if stored incorrectly. The density sits at about 0.83 g/cm³. Chemically, sec-butyl mercaptan features a sulfur-hydrogen bond, making it reactive in both nucleophilic and oxidation reactions. It dissolves in most non-polar organic solvents but separates from water with ease, and its flammability ranks high: open flames spell immediate trouble, while even mild heat risks unwanted vapors. The compound’s structure—C4H10S—provides a backbone for further chemical modification.

Technical Specifications & Labeling

Manufacturers usually sell sec-butyl mercaptan as “sec-butylthiol” or under practical codes referencing its CAS number: 513-53-1. Drums must carry clear hazard pictograms warning of flammability and acute toxicity. Data sheets list purity, water content, acidity, and formation of disulfides or other byproducts. Physical data always includes boiling range, vapor pressure, flash point, and density to inform safe handling. Global transport regulations slot it under UN 2347, signaling hazardous cargo. You’ll see emergency response guides alongside material safety data sheets and up-to-date shelf life recommendations. Facility workers need to pay attention to these specifications to avoid health and safety violations.

Preparation Method

Industrially, sec-butyl mercaptan most often comes from the reaction of sec-butyl chloride with sodium hydrosulfide—an example of nucleophilic substitution at its finest. This approach allows tight process control, and producers use stainless steel reactors to avoid corrosion. Other methods use alkene starting materials through the addition of hydrogen sulfide in the presence of acid catalysts. The choice boils down to scale, costs, and available feedstocks. Purification frequently involves distillation, removal of trace sulfur, and storage under inert gases to stave off oxidation. I remember a small-scale synthesis in college: the pungency left an impression that never faded.

Chemical Reactions & Modifications

Sec-butyl mercaptan displays keen reactivity. Exposing it to oxidizing agents ushers in disulfide formation, which changes its odor and solubility. Alkylation adds complex chains, enabling synthesis of custom thioethers for research or specialty products. Reaction with bases strips hydrogen, preparing sec-butyl thiolate salts for further synthesis. Other researchers use sec-butyl mercaptan as a sulfur source, integrating the functional group into more elaborate organosulfur compounds used in pharmaceuticals, agrochemicals, and rubber additives. Many modifications trace back to simple nucleophilic substitution, showing the richness of organosulfur chemistry in industrial and academic settings.

Synonyms & Product Names

Commercial supplies of sec-butyl mercaptan appear under a handful of names: sec-butylthiol, 2-butanethiol, 1-methyl-1-propanethiol, and secondary butyl mercaptan. Chemical catalogs sometimes list it by systematic nomenclature, but practical applications lean toward the trade names. Handling paperwork, shipping documents, or technical datasheets, I’ve encountered synonyms that rely on either the “mercaptan” or “thiol” suffix—reflecting regional preferences and supplier branding strategies. Each synonym points to the same chemical backbone and hazard risks that require respect in the workplace.

Safety & Operational Standards

Working with sec-butyl mercaptan means exercising real caution. The compound ranks as irritating to skin, eyes, and respiratory passages in short exposures. Acute effects run from mild headaches to full-blown nausea if concentrations rise. Prolonged inhalation can stress liver and kidney function, according to toxicological studies. Storage in explosion-proof coolers, proper grounding of containers, and real-time air monitoring feature in any responsible protocol. Airborne concentrations above 0.5 ppm demand personal protective equipment, and emergency measuring equipment needs constant calibration. Training staff in spill cleanup, ventilation maintenance, and first aid procedures isn’t just a technical guideline—it’s a practical necessity. Facing a spill during a summer internship, I saw rapid evacuation and cleanup efforts save the day.

Application Area

Sec-butyl mercaptan finds its main use as an odorant, especially in LPG and natural gas, where safety calls for unmistakable warning scents. The compound’s volatility and strong odor make it ideal for leak detection. Beyond energy, it shows up in organic synthesis labs as a building block for pharmaceuticals and specialty chemicals, and sometimes as a polymerization modifier. Rubber manufacturing relies on organosulfur compounds for improved durability, and sec-butyl mercaptan contributes to that toughness by crosslinking polymer chains. The food industry steers clear due to toxicity, but trace applications in chemical markers and research surface regularly. I’ve seen its unmistakable odor used as a test in emergency drills across industrial facilities.

Research & Development

Many R&D efforts focus on increasing production efficiency and minimizing environmental impacts of sec-butyl mercaptan synthesis. Recent advances include refining purification steps, reducing formation of malodorous byproducts, and switching to greener starting materials. Analysis of reaction pathways using spectroscopy and chromatography helps scientists understand decomposition and side reactions, particularly under process upscaling. There’s a growing push to design catalysts for milder, safer preparation methods. Academic research explores new uses in organic synthesis—novel ligands, surface modifiers, and precursor compounds for advanced materials. The sheer variety of lab reports, patent filings, and conference talks testifies to the ongoing innovation in this field.

Toxicity Research

Clinical and pre-clinical studies link sec-butyl mercaptan to respiratory, skin, and gastrointestinal disturbances at low concentrations. Ingestion or prolonged inhalation leads to systemic effects—liver and kidney signals routinely appear in animal tests. Regulatory bodies, including OSHA and the European Chemicals Agency, keep updating occupational exposure limits as new data pours in. Researchers turn to inhalation studies, skin patch tests, and simulated workforce exposures to track long-term risks. Absorption through skin or lungs can trigger nervous system symptoms, especially in enclosed spaces or poorly ventilated areas. These toxicity insights reinforce strict containment practices and support ongoing updates to safety protocols.

Future Prospects

Looking down the line, sec-butyl mercaptan will likely keep its place as a go-to odorant thanks to reliability, recognizable scent, and regulatory backing. Technology shifts could drive cleaner synthesis, real-time gas monitoring, and closed-system delivery, all of which cut accidents and reduce unwanted emissions. Demand may rise alongside the expansion of distributed natural gas and renewable energy systems needing leak detection. At the same time, ongoing research into synthetic modifications, improved catalysts, and alternative odorants promotes a dynamic landscape. Efforts to improve workplace safety mesh with moves by regulators and industry to phase out chemicals with persistent health or environmental risks. My experience points to persistent improvements: safety, environmental responsibility, and creative science shaping the future of sec-butyl mercaptan.

The Unmistakable Smell That Saves Lives

Step into any chemistry lab or refinery, and that foul smell isn’t a gas leak or spoiled eggs—someone has uncorked sec-butyl mercaptan. The reason for this chemical’s repulsive odor comes down to a public safety issue. Natural gas on its own gives off no scent. Families and workers would never notice a leak if it weren’t for a detectable warning agent. Sec-butyl mercaptan fills that job. Gas companies blend it into pipelines so leaks don’t slip by unnoticed. In my neighborhood, when the apartments upgraded their lines, people caught a whiff days before the utility got around to warning us. That sharp rotten odor? That saved a few households from a dangerous surprise.

Why Not Just Any Compound?

Safety regulators and chemical engineers want something strong enough that you can’t miss it, but they also need something that won’t stick around or cause its own hazard. Some compounds smell bad but cling to rooms for weeks. Sec-butyl mercaptan disperses more quickly. Its stench triggers concern fast, but a quick venting clears the air once the leak gets fixed. Over time, people learn to recognize it—ask anyone who’s evacuated an apartment, and most will say, “the smell tipped us off.”

Beyond Keeping Homes Safe

Industrial crews use sec-butyl mercaptan for more than gas detection. Oil refineries and chemical plants keep it on hand for leak drills and equipment checks. Trainers can introduce a harmless quantity to test whether staff spot a simulated hazard. Since the chemical mimics the odor found in similar compounds like methyl mercaptan, newcomers learn to watch for problems before a real threat emerges. I’ve seen senior workers use the smell as a “pop quiz,” helping young techs develop a keen nose.

Handling and Health

No one wants sec-butyl mercaptan leaking where it shouldn’t be. Direct exposure brings headaches or nausea, and pollution worries grow if spills reach storm drains. The Environmental Protection Agency monitors how much escapes from industrial sites. Refineries must log and limit their emissions, sending detailed reports to the local authorities. Producers use closed systems and carbon filters to stop leaks, but accidents can happen, especially during transport. Good ventilation and portable detection meters make a difference. Keeping people healthy doesn’t require expensive tools—just strict routines and a habit of not ignoring odors.

Pushing for Safer Practices

Communities press companies to keep public safety above all else. Advocacy groups remind regulators that a single overlooked leak can threaten hundreds of homes. Schools and renters have a right to regular pipeline inspections and clear emergency plans. My city’s fire department now offers free workshops on gas safety, teaching families about the warning smell and what steps to take. It’s easy to take natural gas for granted until the day a room fills with that stink. Lawmakers need to keep holding companies to high standards—nobody wants to gamble with their health over a preventable accident. As for sec-butyl mercaptan, the only time I’m glad to smell it is during training.

Looking Ahead

New tech brings hopes for less toxic, more environment-friendly odorants. Research labs keep searching for alternatives that stand out in an emergency but break down safely. Until that day, everyday vigilance—the willingness to investigate that strange, sulfuric whiff—stays as important as the gas lines themselves.

Understanding the Risks

If you’ve ever caught a whiff of rotten cabbage near a gas leak, you know the telltale stench of sec-butyl mercaptan. This stuff finds its way into natural gas as an odorant so leaks don’t go unnoticed. The same strong smell that helps warn families about danger also tells us something else: this chemical means business and deserves respect in the workplace.

Personal Experience in the Field

I remember my early days on an industrial maintenance crew. Our supervisor didn’t mince words about this compound. He kept a laminated chart of chemical hazards in the break room. His warning for sec-butyl mercaptan always came with stories—guys who skipped gloves and paid the price with persistent rashes or workers who underestimated the fumes, ending up nauseous and needing fresh air. The lessons stuck with us better than any textbook ever could.

Personal Safety Comes First

Sec-butyl mercaptan can irritate skin, eyes, and lungs. Direct contact burns and chokes. No one wants that sort of day. So, protecting your body starts before you ever touch the chemical. Splash-resistant goggles matter more than you’d think. Tight-fitting chemical-resistant gloves keep hands safe, and lab coats or coveralls keep residue off your clothes. In poorly ventilated spaces, a cartridge respirator fights back against airborne fumes. For bigger spills or mixing, go with a full-face shield and extra layers.

Ventilation and Storage

Good air flow makes a huge difference. I’ve seen too many small workshops without enough open windows or exhaust fans. Don’t compromise here—make sure chemical handling areas have strong mechanical ventilation. For emergency rooms and storage spaces, invest in ventilation that will clear the vapors quickly. This stops fumes from pooling and keeps everyone breathing easier. Seal containers tight, label them with clear information, and keep them far away from food, acids, or oxidizers.

Spill Response and Cleanup

Spills seem harmless until you handle one the wrong way. A single drop will fill a room with stink. Sand, earth, or commercial absorbents can contain spilled liquid, but only if you act fast. Don’t use rags or mops—spread keeps growing. Once you’ve cleaned up, bag everything in sealed containers and mark them as hazardous waste. If sec-butyl mercaptan gets on your skin, wash right away with soap and water, even if you don’t see any burns.

Training and Emergency Plans

No one masters chemical safety by accident. It takes practice—fire drills, chemical spill simulations, labeling refreshers. I’ve learned from watching new hires fumble their PPE, or forget the eyewash station location. Keep instructions visible and run drills often. Know how to reach the nearest shower and eyewash station. If someone starts coughing or feeling dizzy, don’t wait—move them to fresh air and call for help immediately.

Protecting People and Planet

Sec-butyl mercaptan floating into a waterway or evaporating into the air isn’t just a workplace headache. Runoff can poison fish and other wildlife, and vapors add to air pollution. That’s why collecting chemical waste and disposing of it through licensed hazardous handlers becomes non-negotiable. Regular inspections catch leaks and weak seals before they turn into bigger problems for both people and the environment.

Building a Culture of Respect and Caution

Safety has a reputation for slowing down the job, but everyone prefers return trips home with all their senses intact. The sharp smell of sec-butyl mercaptan humbles even seasoned pros, reminding us all: with the right gear, alert minds, and a healthy respect for the risks, work can stay productive, healthy, and safe.

The Stuff Smells Like Trouble

My nose still remembers the first time I found myself around Sec-Butyl Mercaptan at a job site. That sulfur punch sticks with you, no matter how careful you try to be. Anyone who works with it knows that just a little leak can turn the air sour fast. This isn’t just about keeping the work floor clean; storing and handling this chemical safely means taking other peoples’ health seriously too.

Fire Risk: Don’t Cut Corners

Sec-Butyl Mercaptan lights up easily. Even a stray spark, a cigarette, or a bit of static can set it off. From experience, you learn to keep it away from open flames or anything that could heat up too much. Storage happens best in rooms with solid ventilation and zero ignition sources. Remember, local codes don’t get made up just to fill paperwork; they follow fires and hard-learned lessons from accidents. Chemical-resistant containers with tight, leak-proof sealing keep vapors where they belong. And grounding those containers stops static from sneaking up on you.

Protecting People: No Time for Shortcuts

Working with Sec-Butyl Mercaptan means pulling on the right gloves, grabbing goggles, and keeping a reliable respirator nearby. This stuff irritates the eyes, lungs, and skin even with short exposure. I have seen coworkers skip protective gear just to “get it done,” and they paid for it with rashes or coughs that lingered for days. Company policies about chemical safety serve more as a lifeline than an obstacle.

Working Against Leaks and Spills

Spills seep into floor cracks and stink up a place for weeks. Keeping spill kits stocked and ready is standard for any responsible workplace. Sorbent pads and neutralizing powders stop a bad situation from getting worse, but the best solution is attention to detail—closing valves, triple-checking seals, and handling containers with steady hands. Clean-up teams need training so mistakes don’t compound danger. Lessons learned in real-world spill drills matter more than anything you pick up from reading a booklet.

The Air Quality Factor

Even in well-ventilated storage areas, it’s worth setting up gas detectors and alarms. The low threshold of detection for its smell doesn’t build enough confidence—your nose adapts after a while, but detectors don’t get tired. Keeping good records on where and how much gets stored is a simple move that helps spot problems before they grow. It also answers questions fast if fire inspectors or regulators come calling.

Preparedness Pays Off

Legal rules around hazardous materials change as new information comes to light or as the workplace changes. Staying informed by checking safety data sheets and local regulations can spare everyone from disaster and fines. I once saw an operation lose business for months over a preventable spill during a warehouse expansion. It wasn’t just the fines; the community lost trust.

Safe storage and careful handling always cost less than an emergency. Everyone on the crew plays a part—from the person watching gauges to the one stocking safety showers and eye-wash stations. Staying picky about safety keeps people healthy and factories running.

Understanding Sec-Butyl Mercaptan

Sec-Butyl mercaptan turns heads for a few reasons. Pick up the bottle, and the strong, skunky odor hits immediately. That’s not a flaw – it’s designed that way. This colorless liquid plays a big role in safety, mostly as a warning agent for dangerous gases. Mix it into natural gas, and any leak becomes impossible to ignore. The low odor threshold means even tiny amounts get noticed, usually at concentrations as low as one part per billion.

Physical Properties that Stand Out

Pour sec-butyl mercaptan, and you watch a clear, mobile liquid pour out. It doesn’t dissolve well in water, which means cleaning up spills takes more than just a rinse. On the technical side, it boils around 90°C (194°F). Its vapor isn’t heavy or sticky but moves with the air and can ignite quickly. Flammability stands out in the list of safety notes – it flashes at about -20°C, way below most working environments. One spark, and the air fills with flammable fumes.

Talking about density, it comes in lighter than water, about 0.84 grams per milliliter. Drip some on the ground, and the liquid spreads, resisting water mixing. Volatility also deserves mention. Caps off in a lab, and the odor dominates the room almost instantly, a sign that vapor pressure isn’t something you can ignore.

Chemical Behavior and Hazards

The key chemical trait of sec-butyl mercaptan lies in its thiol group. This sulfur-hydrogen bond snaps under the right conditions, picking up reactions that release hydrogen sulfide or get transformed into more reactive sulfonic acids. Strong bases and oxidizers set off this change with ease. Anyone working with it needs to respect its reactivity, especially in industrial or research settings.

Toss sec-butyl mercaptan in with chlorinated solvents, and things get complicated fast. Some labs have learned the hard way: mixing those two releases heat and toxic gases, so storage rules matter. There’s no room for mixing and matching bottles under the sink.

In terms of persistence, it sticks around. The smell clings to equipment, and the compound resists easy breakdown in soil or water. Disposal and cleanup add to operational costs, and that’s where experience pays off. Good ventilation, dedicated spill kits, and solid training help keep accidents rare.

Real-World Implications and Fixes

As someone who spent time troubleshooting leaks in a chemical plant, the unmistakable skunk smell raised alarms that saved time and lives. Regulators count on sec-butyl mercaptan because it signals danger before invisible hazards turn deadly. In the field, false alarms frustrate everyone, but nobody prefers the alternative. That early warning buys crucial seconds.

Using sec-butyl mercaptan responsibly calls for strict control – sealed systems, gas detectors, and personal protective gear go beyond checklists. Too many workers ignore thick gloves or proper ventilation, thinking short exposure won’t hurt. Over time, headaches, nausea, and even breathing trouble build up with repeated exposure, so ignoring protocols isn’t worth the risk. Education and routine safety drills can lower incidents and keep exposure down.

Sec-butyl mercaptan might seem just another chemical on a list, but its properties give it real significance. Handling, storage, and accident response require experience and respect for its hazards. Solutions revolve around simple steps done right: awareness, early detection, and strict following of rules.

Why Spills Matter

Sec-butyl mercaptan doesn’t just stink up the place—it poses a serious threat if handled the wrong way. A spill brings headaches: strong odor, flammability, and the potential to harm both people and the environment. In my time around industrial sites, I've watched small leaks quickly grab everyone’s attention because just a whiff tells you something’s wrong.

Stop the Leak, Protect People

Most folks react quickly to strong chemical smells. If I’m onsite and catch the sulfurous odor, personal safety comes first. Evacuating unnecessary personnel buys time. Anyone involved in cleanup pulls on proper gear—respirators, gloves, goggles, and sturdy clothing. Keeping bystanders out and ventilation up reduces the odds of exposure and is standard practice around anything this pungent.

Isolation and Cleanup

Blocking off the floor drain makes a difference. Spill kits come in handy, but speed counts most. Sand, non-sparking tools, and absorbent pads go down right away. Catching runoff could keep this chemical away from city water or soil. In every plant I’ve visited, the emergency response team trains for exactly this. The workers know to cap a leaking valve, check the nearest shutoff, or get to the plant emergency stop. Sometimes it looks like chaos, but there’s a plan behind it.

Dilution Doesn’t Solve the Problem

Sec-butyl mercaptan is tough to neutralize. Dumping water on a spill only spreads the problem and risks vaporizing more of it. In one messy incident, an overzealous worker tried to hose down a slick, filling the air with even more stink. Stopping the leak at its source and scooping up solids or soaking up liquids works better every time.

Proper Disposal: No Shortcuts

Collected waste always heads into sealed, labeled drums built for hazardous materials. Leaving it lying around on a loading dock risks fines, fires, and environmental damage. I’ve heard stories from old-timers about shortcuts, but the smart crews always check their local disposal rules first. Licensed hazardous waste vendors know the ropes and help steer clear of trouble with environmental regulators.

Learning from Each Close Call

An accident isn’t just a mess to clean up; it’s a warning shot. The best-run workplaces I’ve seen use every spill as a lesson. Crews huddle up for debriefs, review what went right, and fix what didn’t. Training improves, equipment gets replaced, and emergency plans get tested for real.

Solutions That Work

Prevention does more than cure ever could. Regular checks on piping and connections catch most problems before they snowball. Installing leak sensors buys precious extra minutes for a response. Employees should know how to identify the smell on day one of their job. Routine drills build muscle memory, so no one freezes up during a real leak. Hazmat teams build trust when staff see their response working in real time.

Safeguarding Community and Environment

A spill that escapes the facility fence can become a public relations headache. Open dialogue with local first responders and neighbors builds goodwill before trouble starts. Practicing good stewardship—tight tanks, routine checks, and a fast response—protects groundwater, air quality, and the business itself.

| Names | |

| Preferred IUPAC name | butan-2-thiol |

| Other names |

sec-Butylthiol

2-Butylmercaptan 2-Butanethiol 2-Butylthiol |

| Pronunciation | /ˈsɛkˌbjuːtɪl mɜːrˈkæpˌtæn/ |

| Identifiers | |

| CAS Number | 513-44-0 |

| Beilstein Reference | 1718732 |

| ChEBI | CHEBI:50534 |

| ChEMBL | CHEBI:35939 |

| ChemSpider | 9649 |

| DrugBank | DB14006 |

| ECHA InfoCard | 03b5f0d9-afb2-4882-85a9-8ce7b25b0f57 |

| EC Number | 200-449-3 |

| Gmelin Reference | 7261 |

| KEGG | C01537 |

| MeSH | D000584 |

| PubChem CID | 7847 |

| RTECS number | EK8575000 |

| UNII | Y07I8P80A2 |

| UN number | UN2347 |

| Properties | |

| Chemical formula | C4H10S |

| Molar mass | 90.19 g/mol |

| Appearance | Colorless liquid with an unpleasant odor |

| Odor | Unpleasant, skunk-like |

| Density | 0.810 g/cm³ |

| Solubility in water | slightly soluble |

| log P | 1.98 |

| Vapor pressure | 19.7 kPa (20 °C) |

| Acidity (pKa) | 10.6 |

| Basicity (pKb) | 3.77 |

| Magnetic susceptibility (χ) | -49.5×10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.4400 |

| Viscosity | 0.67 mPa·s (at 20°C) |

| Dipole moment | 1.60 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 218.7 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -117.6 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -3586.7 kJ/mol |

| Hazards | |

| GHS labelling | GHS02, GHS06, GHS07, GHS08 |

| Pictograms | GHS02,GHS06,GHS07,GHS09 |

| Signal word | Danger |

| Hazard statements | H225, H301, H311, H331, H315, H319, H335, H373, H401 |

| Precautionary statements | P210, P261, P271, P280, P301+P310, P304+P340, P305+P351+P338, P308+P311, P370+P378, P403+P235, P501 |

| NFPA 704 (fire diamond) | 2-4-1-W |

| Flash point | Flash point: -18°C |

| Autoignition temperature | 285°C |

| Explosive limits | 1.5% - 10.4% |

| Lethal dose or concentration | Lethal dose or concentration: LC50 (rat, inhalation) 16,000 mg/m³/4H |

| LD50 (median dose) | LD50 (median dose): 1,790 mg/kg (rat, oral) |

| NIOSH | Al8480000 |

| PEL (Permissible) | PEL (Permissible Exposure Limit) of Sec-Butyl Mercaptan: "0.5 ppm (1.5 mg/m³) as TWA |

| REL (Recommended) | S36/37 |

| IDLH (Immediate danger) | IDHL: 200 ppm |

| Related compounds | |

| Related compounds |

n-Butyl mercaptan

tert-Butyl mercaptan isobutyl mercaptan |